- Double side PCB

- Mutilayers PCB

- HDI circuit boards

- Flexible circuits

- Rigid Flex PCB

- High Frequency PCB

- Metal core PCB

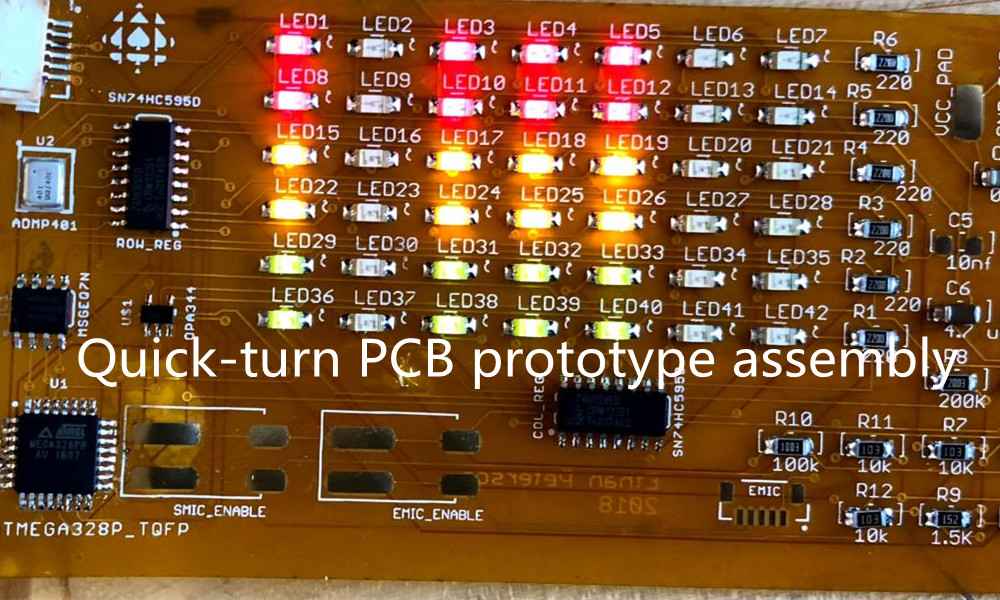

- PCB Assembly

- FPC assembly

- Rigid Flex assembly

Introduction to Flexible Printed Circuit Boards

A flexible printed circuit board (flex PCB or flex circuit) is a type of printed circuit board that is made of flexible insulating material such as polyimide film. Unlike traditional rigid PCBs, flex PCBs can bend and flex while still maintaining their electrical connectivity. Some key advantages of using flex PCBs include:

- Ability to bend and flex to fit mechanically challenging spaces

- Lightweight and thin profile

- Good for high density interconnected assemblies

- Can be folded and wrapped around edges

- Resistant to vibration and fatigue

- Often used in smaller consumer electronics

Flex PCBs are widely used in various industries such as consumer electronics, automotive, aerospace, medical devices and industrial equipment. With the continued miniaturization of electronics, flex PCBs have become an indispensable interconnect solution.

Flex PCB Assembly Process Overview

Assembling a flex PCB involves soldering electronic components like integrated circuits, resistors, capacitors onto the conductive pads and traces on the flex board. It requires specialized skills and equipment to handle the flexible material during assembly. The main steps in flex PCB assembly process are:

1. Design and Fabrication

The first step is design and fabrication of the flex PCB. The PCB layout is designed with CAD software accounting for things like bend radius, layer stackup, controlled impedance etc. The flex board is then fabricated with the required number of conductive layers bonded to the flex substrate. Common flex materials used are polyimide and polyester films.

2. Component Attachment

SMT components are mounted on the board using solder paste and reflow soldering in an SMT assembly line. Larger through hole components may be wave soldered. Adhesives can also be used to attach components.

3. Board Stiffening

Since flex PCBs are flimsy, a stiffener plate is often used under the flex board during assembly to provide support and prevent warping of the board. Temporary stiffeners may be peeled off after assembly.

4. Interconnecting cables/connectors

Cables, connectors and harness assemblies are attached to the flex PCB using soldering, crimping, adhesive bonding etc. to provide power and signals.

5. Conformal coating

A protective conformal coating may be applied to insulate the assembled flex circuit from environmental factors.

6. Testing and inspection

The assembled board is put through electrical tests, automated optical inspection and functional tests. Repairs are conducted if defects are found.

7. Final integration

The tested flex assembly is integrated into the final product such as folding it around hinges or inserting into enclosures. Strain reliefs are added if required.

Flex PCB Assembly Process Steps Explained

Flex PCB Design

- The circuit requirements are analyzed by the engineering team and a schematic is created.

- PCB layout is designed with CAD software based on schematic. Important considerations:

- Bend radius – Avoid sharp folds to prevent traces from cracking. Minimum bend radius is usually defined.

- Stiffeners – Addition of stiffeners to prevent flexing in certain areas.

- Impedance control – Matching trace impedance for high speed signals

- Stackup – Number of conductive layers and dielectric materials used

- Component spacing – Accounting for component density and spacing

- The designed Gerber files are sent to board fabrication facility.

Flex PCB Fabrication

- Raw materials procured – Polyimide films, coverlay, bondply, copper foils, soldermask etc.

- Conductive layers are imprinted on the the polyimide film through a print and etch process.

- Multiple layers are bonded using adhesive or thermocompression bonding to form a multilayer stackup.

- Holes are drilled and plated.

- Soldermask layer is added for oxidation protection.

- Legend printing indicates component locations.

- Electrical testing validates continuity of traces.

- Panels or individual circuits are routed out.

- The finished flex boards are sent for assembly.

SMT Assembly

The surface mount component attachment process involves:

- Solder Paste Printing – Solder paste is printed on to the PCB pads where components will be placed. Stencil is aligned to the PCB and solder paste is squeegeed through the stencil apertures.

- SMT Component Placement – Components are precisely picked and placed on to the solder paste using automated pick and place machines.

- Reflow Soldering – The PCB goes through a reflow oven with a temperature profile to melt the solder paste and attach components.

- Automated Optical Inspection – Cameras inspect the placed components for defects or misalignments.

- Manual touchup – Any defective joints identified are manually touched up.

Challenges specific to SMT assembly on flex boards include:

- Flex boards are thin and bend easily requiring use of stiffeners during assembly.

- They are sensitive to high temperature and thermal shocks.

- Smaller component sizes and spacing require specialized equipment.

- Warpage control is critical.

Through Hole Component Attachment

- Larger components with leads are inserted into plated through holes in the PCB mechanically or by machine.

- The leads are soldered to the plated through holes on the opposite side either by:

- Wave soldering – Passing the PCB over a wave of molten solder

- Selective soldering – Using a specialized soldering head

- Manual soldering – Hand soldering each joint

- Additional support may be provided below the flex board near the through hole components.

- For double sided flex PCBs, through hole component attachment is done after SMT component placement.

Adhesive Component Attachment

Some components are attached to the flex PCB using adhesives rather than soldering:

- Surface mount adhesive placement – An adhesive paste or film is screen printed on the board. The component is then placed on top and adhesive is cured with heat or UV.

- Dispensing liquid adhesive – A syringe or needle dispenses a small dot of adhesive on the board and component is placed on top.

- Preapplied adhesive on component – Adhesive is pre-applied to the component terminals which sticks to the board upon placement.

Adhesives provide mechanical attachment as well as electrical connectivity in some cases. Useful for attaching SMTs to challenging areas or uneven surfaces on flex boards.

Stiffener Use

Since flex PCBs can bend and warp during assembly, stiffeners or rigidizers are commonly used as mechanical support.

Types of Stiffeners:

- Removable stiffeners – Acrylic or metal plates are temporarily attached below flex board during assembly but removed afterwards prior to flexing the circuit.

- Permanent stiffeners – FR4 boards or metal plates that are permanently attached to certain areas of the flex circuit that need to remain rigid.

- Discrete stiffeners – Small stiffeners attached only under certain large components or connectors.

- Tooling holes – Additional holes used for pins to hold the PCB flat during assembly.

Stiffener Application Methods:

- Screwing – Metal stiffeners screwed into tooling holes or mounting holes.

- Clamping – Sandwiching board between clamps and plates.

- Adhesive attachment – Sticky acrylic or epoxy stiffeners.

- Soldering – Soldering metal stiffeners. Needs to withstand reflow temps.

Interconnect Attachment

Cables, wire harnesses and connectors are attached to the edge of the flex board to provide power, signals and connectivity.

Some approaches include:

- Soldering – Wires soldered to designated pads on the flex board.

- Crimping – Using mechanical crimps that pierce conductor insulation and grip wires.

- Insulation displacement – Using IDC connectors that slice through wire insulation to make contact.

- Application of anisotropic adhesive – Conductive adhesive film or paste.

- Z-axis conductive elastomer – Using conductive rubber connectors.

Reinforcement such as heatshrink tubing may be used over soldered wire connections. Strain relief is critical for long term reliability of interconnects.

Conformal Coating Application

Conformal coatings are thin protective layers applied on top of the assembled PCB. This provides:

- Environmental protection from moisture, dust etc.

- Mechanical support by binding components together.

- Electrical insulation between traces.

Popular conformal coating materials:

- Acrylic – Most common and cost effective. Easy to apply and repair.

- Silicone – Withstands high temperatures. More flexible.

- Urethane – Abrasion resistant.

- Parylene – Extremely thin pinhole free coating. Expensive.

- Epoxy – Hard and durable but difficult to apply and repair.

Application process:

- Cleaning – Ensure board is free of contaminants.

- Masking – Cover areas like connectors or testpoints that must remain uncoated.

- Coating – Applied via dipping, spraying, or brushing.

- Curing – Heat or UV cures the liquid coating into solid protective film.

Testing and Inspection

Multiple tests required to validate flex PCB assembly:

- Visual inspection – Verify all components placed and solder joints look good. Check for any defects.

- In-circuit test (ICT) – Applies test probes to test electrical continuity of circuits according to netlist.

- Flying probe – Tests connectivity of points on bare boards prior to component placement.

- Functional test – Validate assembled board works as intended by exercising it’s functions.

- Automated X-ray inspection – Looks for hidden defects like voids under BGAs.

- Endoscope inspection – Use endoscopic cameras to inspect assemblies from multiple angles.

- Resistance measurements – Use multimeter probes to measure resistance values on the board.

Any defects found during testing are diagnosed and corrected. Faulty components replaced and solder joints reworked. The board goes through testing again until no errors found.

Final Integration

The fully assembled and tested flex board is integrated into the end product:

- Carefully folded, bent or wrapped around hinges and edges as originally designed.

- Strain reliefs added to connectors or cables.

- Attached to enclosures through mounting holes or adhesive.

- Connected to mating connectors in the product.

- Additional mechanical parts assembled – shields, holders etc.

This completes the flex PCB ready for use in the finished product. Proper flex PCB assembly process planning and workmanship is critical to ensure a reliable, functional and robust flex circuit assembly.

Flex PCB Assembly Equipment

SMT Assembly Equipment

- Flexible board handling conveyors – Adjustable vacuum conveyors grip flex boards securely during transport through assembly line.

- Flexible board support tooling – Such as vacuum plates below board or specialized clamping.

- Thin board capable pick and place – Machines that can handle thinner boards and smaller components.

- Dual lane transport rails – Allows loading stiffened and non-stiffened boards on separate lanes.

- Dedicated flexible board reflow – Reflow ovens with adjustable heaters and cooling to control warpage.

- Preheaters – Gradual controlled ramp up to reflow temperature.

hrough Hole Assembly Equipment

- Pin through hole plating – For double sided boards to allow TH insertion after SMT components.

- Press-fit assembly – Allows attachment of some TH components without soldering.

- Robotic soldering – For repeatable automated TH soldering and inspection.

Other Equipment

- Dedicated flexible board wave soldering – Better control of heat exposure time, contact angle etc.

- Conformal coating systems – Precision spray or coating robots optimized for coating flex boards consistently.

- Flexible optical inspection – Advanced optical inspection systems that can handle flex board warpage.

- Flying probes – Allows electrical test of tracks before component placement.

- X-Ray inspection – Detect hidden defects like voids under BGAs post-soldering.

Test Systems

- Bed of nails test fixtures – Reliable temporary connections to testpads on flex circuits.

- Flying probe testers – Automatic probes test electrical nodes without test fixture.

- Functional board test stands – Simulate real world loading conditions.

The right specialized tooling and processes for flex materials can greatly improve assembly quality and yield.

Flex PCB Assembly Challenges

Warpage and Wrinkling

The flexible thin material is prone to warping and wrinkling during assembly operations:

Causes

- Thermal gradients during soldering

- Uneven distribution of components

- Shrinkage of adhesive during curing

- Internal stresses in the material

Solutions

- Optimize heating and cooling rates during reflow

- Add stiffeners and carrier plates for support

- Distribute components evenly to balance stresses

- Carefully controlling adhesive cure process

Registration and Tolerance Control

The flex board material can shrink and expand leading to misregistration issues:

Causes

- Coefficient of thermal expansion mismatches

- Stretching and shrinkage of flex material

- Accumulation of tolerances in assembly process

Solutions

- Tight tolerance tooling pins and fixtures

- Vision alignment systems for accurate placement

- Panel based assembly to minimize handling

- Laser trimmed boards post assembly to improve tolerance stackup

Soldering Issues

It can be challenging to solder small joints on thin, bendable material:

- Insufficient heat transfer due to board thickness

- Reduced capillary action of solder paste

- Shadowing of joints under components

- Solder beading along panel edges

Solutions

- Specialized soldering equipment for flex boards

- Solder paste dispensing optimization

- Solder masks to limit solder spreading

- Focused heat technology for shadowed joints

Cleaning and Contamination

Thin flex circuits are prone to contamination which can lead to assembly defects:

Causes

- Flex material texture can trap contaminants

- Cleaning solvents can remain under components

- Components can be damaged during cleaning process

Solutions

- Specialized cleaning methods tuned for flex boards

- Post-soldering and post-assembly cleaning processes

- Assembling in cleanroom environment as much as possible

Via Reliability

Plated through holes on flex boards are susceptible to cracking:

Causes

- Flexing stresses can propagate cracks in plating

- Poor adhesion between flexible base material and plated barrel

- Exposure to thermal shock during assembly

Solutions

- Reduce use of plated through holes and vias if possible

- Optimize plating thickness and surface treatment

- Reinforce vias with conformal coating.

- Carefully control temperature ramp rates

Flex PCB Assembly Defects

Pad cratering – Due to excess flexing of the thin laminates during assembly the pad may crack and separate from the base copper.

Solder balls – Excess solder leaves unwanted solder balls that can lead to shorts.

Shadowed joints – Components like connectors may shadow joints underneath preventing proper solder fillet formation.

Isolated joints – Where a solder joint gets isolated from the rest due to flexing and develops cracks.

Solder beading – Solder builds up unevenly along the flex board edges.

Misregistration – Components placed incorrectly due to material expansion and shrinkage.

Tombstoning – Where SMT components stand up vertically due to uneven solder reflow.

Adhesive oozing – Excess adhesive coming out from under components.

Fold damage – Cracks or broken traces along flex fold lines.

Via cracks – Stress cracks in plated through hole barrels leading to opens.

Contamination – Foreign particles lodged under components or blocking solder flow.

Many of these defects can be prevented with optimized assembly processes for flex boards and regular inspection.

Flex PCB Assembly Guidelines

Here are some key guidelines to follow for reliable flex PCB assembly:

- Board handling – Use vacuum platen, edge clamps and minimal direct contact to avoid scratching traces. Handle panels instead of individual boards where possible.

- ESD control – Follow proper ESD procedures as flex boards are more prone to static discharge damage. All assembly staff should be grounded.

- Stiffener use – Stiffeners are required during most assembly steps to avoid warpage. But remove any temporary stiffeners prior to flexing.

- Soldering – Use a reflow profile optimized for the flex board materials. Generally lower peak temperatures and longer times above liquidus.

- Adhesives – Avoid adhesive overflow or seepage. Apply smallest amount needed and ensure adequate curing.

- Cleaning – Use recommended flex board cleaning methods. Avoid high pressure sprays directly on components.

- Inspection – Inspect for soldering and placement defects under magnification. Conduct electrical testing. X-ray for hidden issues.

- Protective coating – Apply conformal coating for mechanical and environmental protection. Mask connectors.

- Packaging – Use antistatic bags or tubes for storing populated flex boards. Avoid kinking or creasing the boards.

With the right assembly process planning, tooling and operator training, high yields and reliable flex PCB assemblies can be achieved.

Flex PCB Assembly Process Flow Chart