Quick Turn Assembly

Quality Assurance

MOQ Requirements

24 Hours Service

PCB Services

PCB and PCB Assembly maunfacturer

GREATPCB SMT LIMITED established PCB factory in Shenzhen 2002,and built PCB Assembly factory in 2008 . We are professional PCB &PCB assembly manufacturer for more than 15 year. we can provide one stop services from PCB (1-20 layers) to PCBA including sourcing Components ,Programming IC,Conformal Coating, Function and Aging Testing.

Our Advantages

PCB/PCBA/FPC Fabrication, Assembly, Components, Design, and Box Builds under One Roof.

PCB/PCBA/FPC Fabrication, Assembly, Components, Design, and Box Builds under One Roof.

Our Solutions

Our solutions cover multiple fields, including Communication, Semiconductors, Medical Devices, Digital Electronics, Industrial Control, and Transportation. We offer full customization and one-stop services

Types Of PCB Materials

- Multiple High-Frequency Board Options (e.g., Rogers)

- Solder Mask Bridges, Via Plugging Process

- Blind and Buried Via Technology

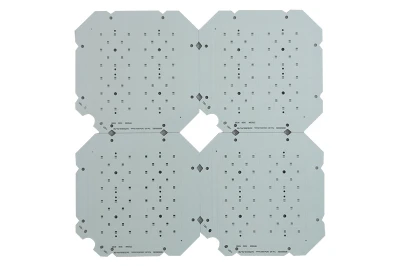

Double-sided aluminum PCB

Types Of PCB Materials

High Frequency PCB

- Multiple High-Frequency Board Options (e.g., Rogers)

- Solder Mask Bridges, Via Plugging Process

- Blind and Buried Via Technology

HDI PCB

- Custom Copper Cladding

- Blind and Buried Vias

- Copper Filling

- Microvia Technology

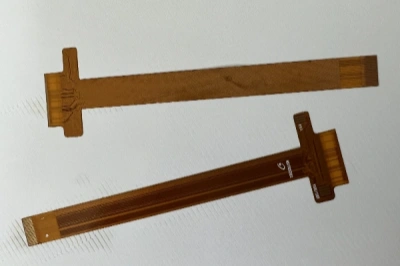

Flex PCB

- Flexible Reinforcement Materials

- Antistatic Coating

- Custom Printing

- Waterproof Coating

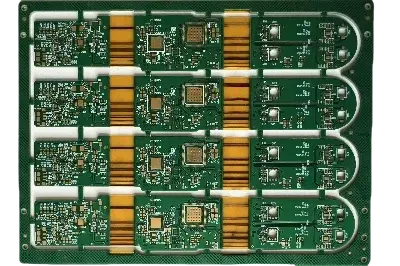

Rigid Flex PCB

- Custom Enclosures

- Thermal Management Solutions

- Flex-Rigid Layer Stacking

- Insert Molding

Double-sided aluminum PCB

- Surface Finishing

- Precision Copper Foil Lamination

- High-Temperature Resistant Coating

Heavy Copper PCB

- Heavy Copper Plating

- High-Performance Surface Finishing

- Cooling Channel Design

Advanced PCB Technology

PCB and PCB Service

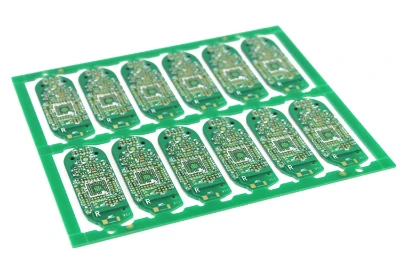

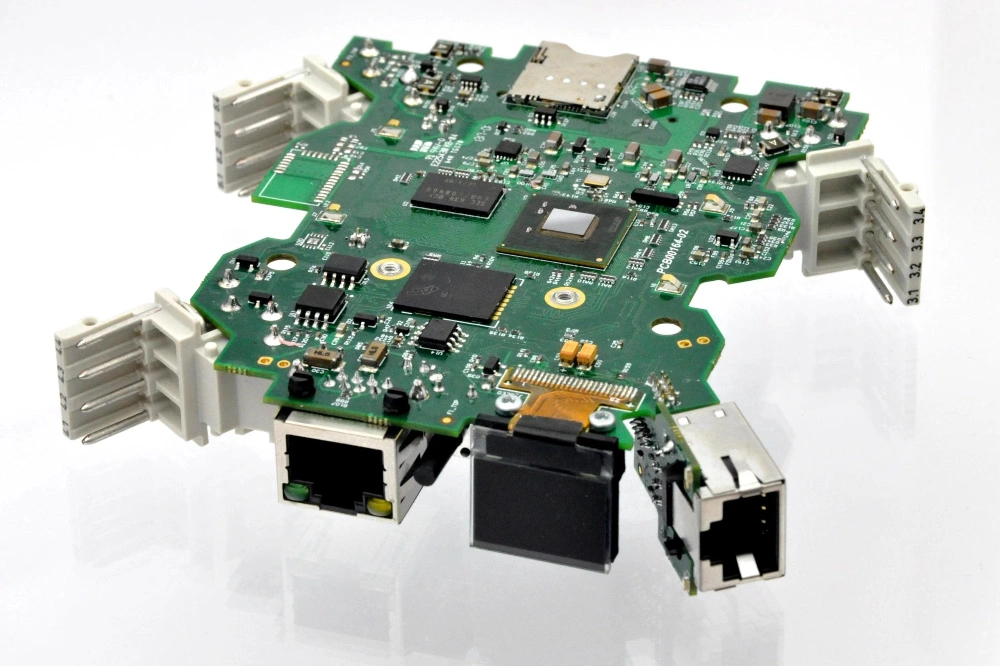

PCB Assembly

Flex PCBs offer unique advantages in applications where flexibility, space savings,and reliability are critical.Their ability to conform to non-planar surfaces and withstand dynamic conditions makes them a preferred choice for a wide range of industriesand innovative productdesigns.

Flex PCB

PCB assembly is a critical process in electronics manufacturing, and the quality of the assembly directly impacts the performance and reliability of the final product,including component placement,soldering,inspection, and function testing.

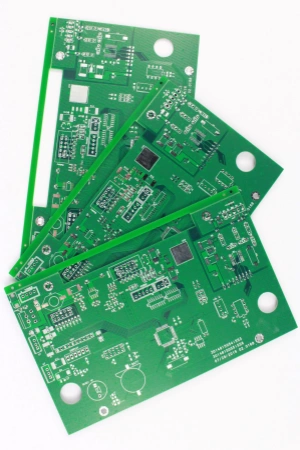

Standard PCB

Standard PCBs serve as the foundation for electronic circuits and provide a reliable and cost-effective solution for a wide range of applications. Their adherence to industry standards and specifications makes them versatile, accessible. and suitable for diverse electronic design projects.

Metal PCB

Metal Core PCBs play a crucial role in thermal management for electronic devices, offeringa reliable solution for applications that require efficient heat dissipation and enhanced performance.By everaging the thermal conductivity of the meta core.

Design PCA

Designing a PCA (PrintedCircuit Assembly) involves creating a layout for the components and circuitry on a printed circuit board(PCB) to meet the functional requirements of the electronic device. Our engineering team has significant real world experience designing PCBS

Component Procurement

Component procurement is a crucial aspect of the PCB assembly process,involving the sourcing and purchasing of electronic components needed for the assembly of printed circuit boards ,including IC chip. resistors,capacitors, inductors,transformers, connectors,buttons, displays, sensors and so on.

PCB and PCB Assembly factory

We have three factories: one for PCB production, one for PCB assembly, and one for FPC manufacturing, with a total of 500 employees. Our automated equipment significantly boosts efficiency and product quality. The PCB factory produces around 15,000 square meters of boards per month, while the assembly plant completes about 10,000 units per month. Our FPC facility handles around 8,000 flexible circuits monthly. With stringent testing and quality control processes, we ensure high standards and fast delivery to meet urgent electronics project demands.

PCB and PCB Assembly factory

We have three factories: one for PCB production, one for PCB assembly, and one for FPC manufacturing, with a total of 500 employees. Our automated equipment significantly boosts efficiency and product quality. The PCB factory produces around 15,000 square meters of boards per month, while the assembly plant completes about 10,000 units per month. Our FPC facility handles around 8,000 flexible circuits monthly. With stringent testing and quality control processes, we ensure high standards and fast delivery to meet urgent electronics project demands.

.jpg)