High Frequency

Assembly

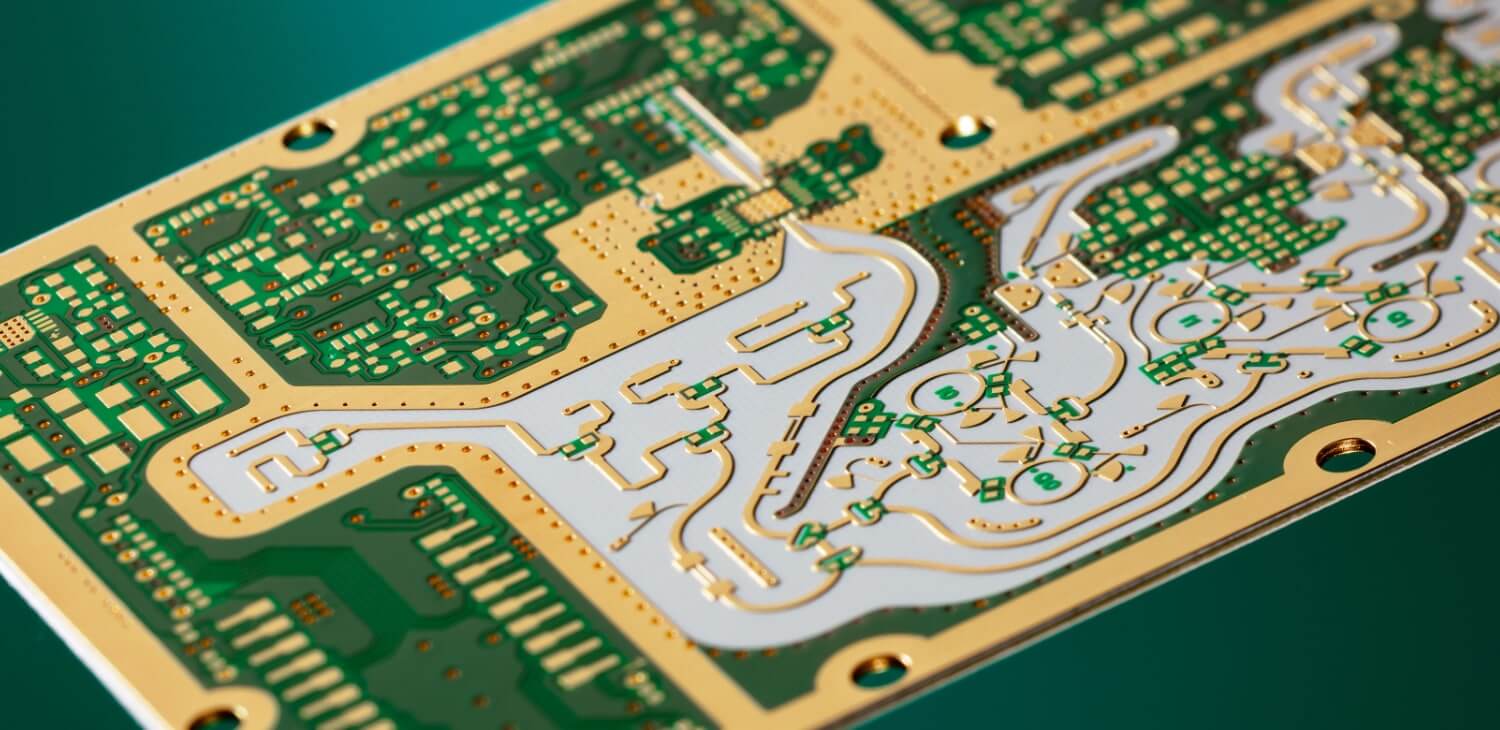

What Is Rogers PCB ?

Rogers PCB is a high-performance printed circuit board substrate material using Rogers’ unique amide resin material, laminated with specialized materials commonly used for high frequency and high speed applications. It has excellent dielectric performance, thermal stability and mechanical strength, and can operate reliably under strict conditions such as high temperature, high humidity and high frequency and high speed conditions.

Rogers PCB Application

all kinds of microwave equipment, cellular base station antennas and power amplifiers, microwave point-to-point (P2P) links, automotive radar and sensors, radio frequency identification (RFID) tags, live broadcast satellite LNB, 5G communication development.

Differences Between Rogers PCBs and Traditional PCBs (e.g., FR-4)

- Material Composition

Rogers PCBs use ceramic or special polymer materials, while FR-4 is primarily composed of epoxy resin and fiberglass. Rogers materials have superior dielectric properties, making them suitable for high-frequency applications. - Performance Differences

- Dielectric Constant (DK): Rogers PCBs have a lower and more stable DK value with frequency changes, helping to reduce reflections and losses during signal transmission; FR-4 has a higher DK value that varies significantly with frequency.

- Temperature Stability: Rogers PCBs have excellent temperature stability, suitable for operation over a wide temperature range; FR-4 may experience performance degradation in high-temperature environments.

- Moisture Absorption: Rogers PCBs have extremely low moisture absorption, making them suitable for high-humidity environments; FR-4 is relatively more prone to moisture absorption, which can affect electrical performance.

- Cost and Applications

Although Rogers PCBs have higher material costs, their outstanding performance makes them particularly suitable for applications with stringent performance requirements; in contrast, FR-4, being lower in cost, is widely used in the manufacturing of general electronic products. - Processing Compatibility

Despite the different materials, the processing techniques for Rogers PCBs are somewhat compatible with those for FR-4, providing manufacturers with more options.

Classic Products of Rogers PCBs

- 3000 Series (PTFE + Ceramic/Fiberglass, DK=3.0-10.2): RO3003, RO3003G2, RO3035, RO3006, RO3010, RO3203, RO3206, RO3210

- 4000 Series (Hydrocarbon + PTFE, DK=3.38-6.15): RO4350B, RO4003C, RO4835, RO4360G2

- (Hydrocarbon + PTFE + Ceramic Fiberglass, DK=3.3-3.5): RO4533, RO4534, RO4535, RO4725JXR, RO4730JXR, RO4730G3

- 5000 Series (Fiberglass + PTFE, DK=1.96-2.33): RT/Hard Composite 5880, RT/Hard Composite 5880LZ, RT/Hard Composite 5870

- 6000 Series: Suitable for electronic circuits and microwave circuits requiring high dielectric constants.

- (PTFE + Ceramic, DK=2.94-10.2): RT/Hard Composite 6002, RT/Hard Material 6202PR

- TMM Series (Hydrocarbon + Ceramic, DK=3.27-12.85): TMM3, TMM4, TMM10, TMM10i, TMM13i

- Others: Kappa 438

- Prepregs: RO4450B, RO4450F

- Adhesive Films: 2929, 3001, ULTRALAM3908, RO3003, RO3006, RO3010, RT/Hard Composite 6002