The Advantages and Disadvantages of ICT and FCT in PCBA Testing

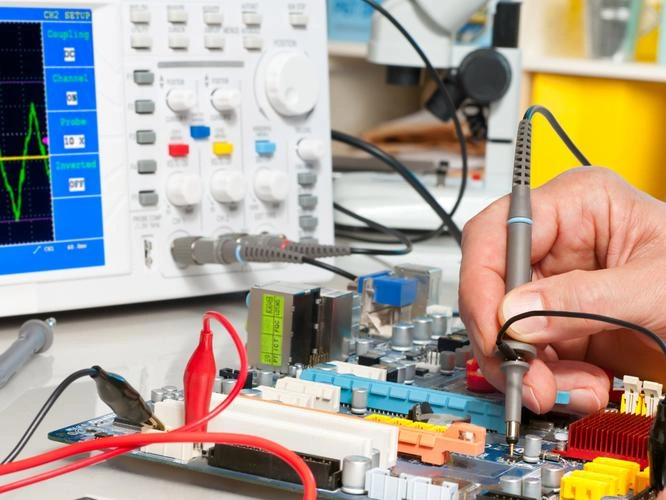

Stringent Testing Required Before PCBA Delivery

Before delivering a PCBA (Printed Circuit Board Assembly) to customers, it must undergo rigorous electrical and performance testing. FCT (Functional Circuit Testing) and ICT (In-Circuit Testing) are the two main testing methods used in PCBA testing. Although ICT became the mainstream method when PCBA first emerged, many large electronic design companies still use ICT to rigorously test original products. This ensures that the components on the circuit board meet the design values and parameters, thus preventing failures.

The FCT test fixture mainly conducts functional tests on finished PCBAs. It simulates the product’s working environment and assesses various states to verify the functionality of the target board. Both ICT and FCT test fixtures are commonly used in electronic product manufacturing lines.

Testing Equipment and Methodologies

ICT (In-Circuit Testing) Electrical Performance Testing Equipment:

ICT involves testing the circuit without breaking it or removing any components. It checks for short circuits, open circuits, and various electronic components such as resistors, capacitors, diodes, transistors, and ICs. It identifies issues like incorrect parts, missing parts, faulty components, and assembly defects. It can also pinpoint the exact location of the defect, helping users ensure product quality and improve repair efficiency.

FCT (Function Tester):

FCT builds upon ICT by powering the circuit board under test and using functional test modules to perform a series of product function tests. These can include testing LED modules, audio modules, IC programming, voltage measurements, and communication tests.

Testing Principles

ICT (In-Circuit Testing):

ICT primarily works by using a bed of nails fixture to contact the test points on the PCBA, applying a certain current and voltage to detect parameters such as open circuits, short circuits, and resistance. It is a testing method based on circuit structure and focuses on the physical characteristics of the circuit.

FCT (Functional Testing):

FCT, on the other hand, is based on the product’s functional requirements. It simulates the actual working environment to validate the various functions of the PCBA. The primary focus is on verifying that the product’s functions are operating normally and meeting design requirements.

Application Scope

ICT:

ICT is generally used for mass testing on production lines, quickly identifying common defects such as open circuits and short circuits on PCBAs to ensure the basic electrical performance of the product.

FCT:

FCT is typically employed in the final testing stage of a product to verify that the product’s overall functionality meets design requirements. FCT is more focused on validating the product’s performance and functionality in actual application scenarios.

Testing Objectives

ICT:

The main goal of ICT is to ensure the proper physical connections and electrical performance of the PCBA and to identify any possible manufacturing defects. It primarily focuses on verifying the basic performance and connectivity of the circuit.

FCT:

FCT’s primary objective is to confirm that all functions of the product operate correctly, ensuring that the product meets design requirements in real-world applications. FCT places more emphasis on the product’s performance and functionality in practical usage scenarios.

The Declining Use of ICT and the Rise of FCT

ICT and FCT each have their own focus in PCBA testing. ICT is mainly concerned with the physical properties and basic performance of the circuit and is suitable for mass testing on production lines. FCT, however, is more focused on verifying the product’s actual functions and performance and is generally used in the final testing phase of the product. Both play a crucial role in the electronics manufacturing industry, and their combined use can more effectively ensure the quality and performance of the PCBA.

With the rapid development of the semiconductor industry, the density of electronic components is increasing, and production processes and stability are becoming more mature. This has led to a narrowing of the application scope of ICT testing. Many small to medium-sized PCBA electronics manufacturing plants no longer prioritize ICT testing as their primary method but instead are shifting towards FCT functional testing. Factories often require customers to provide an FCT testing plan, including test procedures, test fixture issuance, and related test steps, to facilitate FCT testing before delivery to customers.

Cost and Efficiency

Another reason for FCT’s growing dominance over ICT is cost. FCT is relatively inexpensive and can be customized based on the customer’s design. The cost of a test fixture typically ranges from $200 to $1000. Additionally, ICT requires coverage of many components, making the manufacture of the test pin platform complex and expensive. Therefore, ICT testing is now more commonly used in high-volume general-purpose equipment and production lines.

In PCBA testing, ICT is akin to using multiple multimeters to measure component values, with an ICT coverage rate of approximately 90%. FCT simulates testing of the entire machine or the extreme load of the power supply board, with a coverage rate of around 70%. Currently, many factories use ICT testing first, followed by FCT testing, combining both methods to achieve a coverage rate of over 95%.

Related Posts

PCBA Prototype

December 14, 2025

PCB Assembly

September 2, 2025