Understanding CTI and PTI Tests for Insulating Materials

By PCBA PrototypePublished On: 2025-05-09Categories: Uncategorized0 Comments on Understanding CTI and PTI Tests for Insulating Materials

By PCBA PrototypePublished On: 2025-05-09Categories: Uncategorized0 Comments on Understanding CTI and PTI Tests for Insulating Materials

The tests of the relative tracking index (CTI) and the proof tracking index (PTI) of non-metallic materials are important safety parameters in the general inspection items of electrical appliances. These tests mainly simulate the inspection of whether the conductive substances deposited on the surface of non-metallic materials by charged components of different polarities during the actual use of electrical appliances will cause the risks of creeping discharge, breakdown short circuit and fire. They are important test methods for evaluating the tolerance of non-metallic materials under the combined action of the above-mentioned electric field and polluted electrolyte.

What are CTI and PTI?

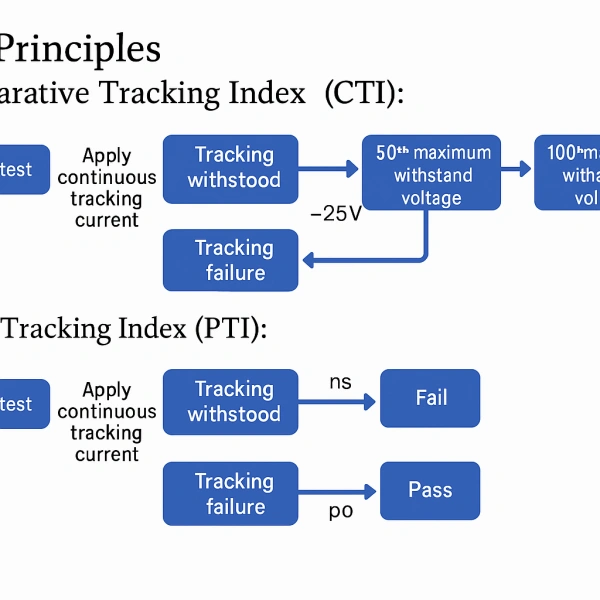

CTI is the abbreviation of Comparative Tracking Index, and in Chinese it is the relative tracking index. CTI is the highest voltage value at which the surface of an insulating material can withstand 50 drops of electrolyte (0.1% ammonium chloride aqueous solution) without forming tracking marks, with the unit being V.

PTI is the abbreviation of Proof Tracking Index, and in Chinese it is the proof tracking index. PTI is the withstand voltage value corresponding to the situation where five specimens do not have tracking failure and continuous combustion after being subjected to the action of 50 drops of electrolyte (0.1% ammonium chloride aqueous solution) at a rate of one drop every 30 seconds, with the unit being V.

The difference between CTI and PTI is that CTI is used to find out the maximum voltage that will not cause the damage of the arc trace of the material by changing the applied voltage, while PTI indicates whether the test voltage can be withstood. In other words, CTI is like the exams in senior high school, where it is acceptable to fail but one should achieve the best score, and PTI is like the exams in university, where one must pass, otherwise it is regarded as a failure.

Application Scenarios

It is applicable to the research, production and quality inspection departments of lighting equipment, low-voltage electrical appliances, household appliances, machine tool electrical appliances, motors, electric tools, electronic instruments, electrical measuring instruments and information technology equipment. It is also applicable to the industries of insulating materials, engineering plastics, electrical connectors and auxiliary parts.

Influencing Factors of CTI Test Parameters

Influencing Factor 01 Electrode Material

According to the requirements in the test standard, platinum electrodes with a minimum purity of 99% should be used. This is because platinum has stable chemical properties and is not likely to react with the electrolyte and the sample. Currently, many laboratories basically know to use platinum electrodes, but they tend to overlook the requirement for purity. When platinum electrodes with lower purity are used, chemical reactions are likely to occur, which may accelerate the tracking of the material. The purity of the platinum electrodes used in Huazheng CNAS Laboratory reaches 99.99%.

Influencing Factor 02 Electrode Pressure

During the test, the surface force of the electrodes on the specimen is (1.0 ± 0.05) N, and it can also be converted into equivalent mass, which is (96.94 – 107.14) g. The main function of this pressure is to ensure stable contact between the electrodes and the sample. And it is required that the pressure should be kept as constant as possible during the test. This requirement is likely to be overlooked by the laboratory, and the equipment itself does not have relevant instruments and equipment to monitor this pressure, so it needs to be monitored regularly.

Influencing Factor 03 Electrode Cleaning and Grinding

After the test, the phenomenon of material failure often occurs on the electrodes, and the pollution of the electrodes will be more serious. If it is not cleaned in time, with the increase of pollutants, it will affect the test results and lead to material failure. It is recommended to clean the electrodes with alcohol before and after each test, and regularly use mechanical methods, such as sandpaper grinding, to ensure the cleanliness of the electrodes.

Influencing Factor 04 Configuration of Ammonium Chloride Solution

The concentration of the ammonium chloride solution directly affects the test results of the experiment. The higher the concentration of the electrolyte, the longer the time for forming the conductive path between the electrodes, and the longer the time for the electric field acting on the surface of the sample. As a result, the test will be stricter, and the measured tracking index of the sample will be smaller. Conversely, the test result will be larger. Therefore, the electrolyte should be configured strictly in accordance with the standard. Among them, the purity requirement of ammonium chloride is not less than 99.8%, the conductivity of deionized water does not exceed 10 uS/cm, the resistivity of the configured solution at 23 ± 1℃ is 395 ± 5 Ω/cm, and the corresponding conductivity range is (2500 – 2566) uS/cm. If the configuration method of mass fraction is still used according to the old version of the standard method during the test, and the conductivity or resistivity of the solution is not confirmed, it will have a great impact on the test results.

Influencing Factor 05 Size of Droplets

The test requires that the weight of 50 consecutive droplets is between 0.997 – 1.147 g, and the weight of 20 consecutive droplets is between 0.380 – 0.480 g. During the test, if the mass of the droplets is too large, more ions will be provided per unit time, which will accelerate the tracking of the sample. On the contrary, if the mass of the droplets is too small, it will affect the rate of solvent volatilization by the heat source, resulting in a decrease in the ion concentration in the remaining electrolyte on the specimen, thus slowing down the formation of the conductive path between the electrodes and affecting the test results.

Related Posts

PCBA Prototype

December 14, 2025

PCB Assembly

September 2, 2025