What Is Alumina Ceramic PCB?

By PCBA PrototypePublished On: 2025-07-28Categories: Uncategorized0 Comments on What Is Alumina Ceramic PCB?

By PCBA PrototypePublished On: 2025-07-28Categories: Uncategorized0 Comments on What Is Alumina Ceramic PCB?

Alumina ceramic PCB are a standout type of ceramic substrate that has seen explosive growth in recent years. Why? Because they excel in thermal conductivity, electrical insulation, and pressure resistance—making them indispensable in countless industries and a go-to choice for engineers and manufacturers alike. Today, we’re diving into what alumina ceramic substrates are, their key features, how they’re classified, and even how to spot a high-quality one. Plus, we’ll share why GreatPCB is your trusted partner for ceramic substrate PCB prototyping.

What Is an Alumina Ceramic PCB?

At its core, an alumina ceramic substrate is a specialized material where aluminum oxide (Al₂O₃) ceramic serves as the main component. Alumina ceramic itself is prized for its impressive combination of properties: strong thermal conductivity, high mechanical strength, and excellent resistance to high temperatures. These traits have made alumina ceramic substrates a staple in modern technology, bridging the gap between everyday applications and high-performance industrial needs.

Alumina ceramics are broadly divided into two categories: general-purpose and high-purity. Today, we’re focusing on general-purpose alumina ceramic substrates, which are the workhorses of the industry.

General-Purpose Alumina Ceramic Substrates: Classified by Al₂O₃ Content

General-purpose alumina substrates are categorized based on their aluminum oxide content, with common grades including 99%, 95%, 90%, and 85%. Sometimes, grades with 80% or 75% Al₂O₃ are also grouped into this family. Each grade has unique strengths:

- 99% alumina : With nearly pure aluminum oxide, this grade thrives in extreme conditions. It’s used to make high-temperature crucibles, refractory furnace tubes, and ultra-wear-resistant parts like ceramic bearings, seals, and water valve discs.

- 95% alumina : A balance of durability and cost-effectiveness, this grade is ideal for corrosion-resistant and wear-resistant components, making it a favorite in industrial machinery.

- 85% alumina : Often blended with talc to boost electrical performance and mechanical strength, this grade bonds well with metals like molybdenum, niobium, and tantalum. It’s commonly used in vacuum electronic devices and components requiring reliable metal-ceramic seals.

Key Properties of Alumina Ceramic Substrates

What makes alumina ceramic substrates so popular? Let’s break down their star qualities:

1. Exceptional Thermal Conductivity

Alumina ceramic substrates are heat-dissipation champions, with thermal conductivity typically ranging from 30W to 50W/m·K. Thinner substrates conduct heat even more efficiently, while thicker ones are slightly less conductive—but even at their “slowest,” they outperform regular PCBs by 100x or more. This makes them critical for devices generating lots of heat, like high-power LEDs or industrial modules.

2. Low Thermal Expansion

As an inorganic ceramic material, alumina is hard, pressure-resistant, and has a low thermal expansion coefficient. This means it rarely warps or deforms, even when exposed to rapid temperature changes—keeping circuits stable and reliable.

Common Types of Alumina Ceramic Substrates

Alumina ceramic substrates come in various forms, each tailored to specific uses. Here are the most common types:

1. Alumina Substrates for Chip Resistors

These are the most widely used alumina substrates, thanks to their relatively straightforward manufacturing process. They’re typically made using tape casting: a method where ceramic slurry is spread into thin sheets, dried, and fired. For 96% alumina substrates, mineral additives act as fluxes, allowing them to fire at a lower temperature (1580–1600°C) while still achieving a high density of over 3.75g/cm³.

Why they’re great: They’re small, lightweight, heat-resistant, and highly insulating, with low dielectric loss. Their thermal expansion closely matches that of electronic components, boosting circuit reliability and enabling denser wiring—perfect for chip resistors.

2. Alumina Substrates for Thick-Film Hybrid Circuits

These substrates are built to handle extreme conditions, withstanding up to 50,000 thermal cycles—making them ultra-reliable. Like PCBs or IMS substrates, they can be etched into complex patterns, and they’re eco-friendly (no toxic byproducts). Their thermal expansion is nearly identical to silicon, simplifying the production of power modules.

Tape-cast versions are exceptionally flat and smooth, with strong electrical performance, high thermal conductivity, and robust mechanical strength. They’re used in ceramic-clad copper plates, thick-film circuits, and ceramic heating elements.

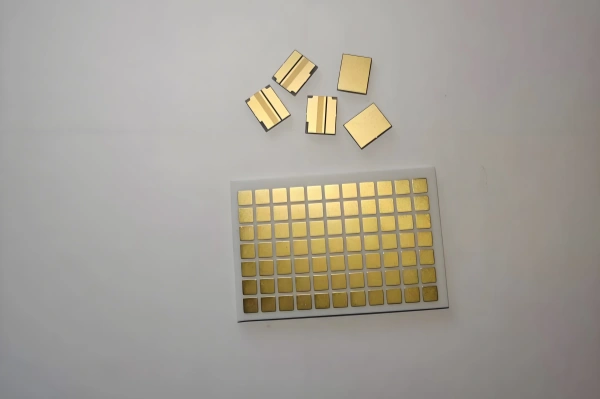

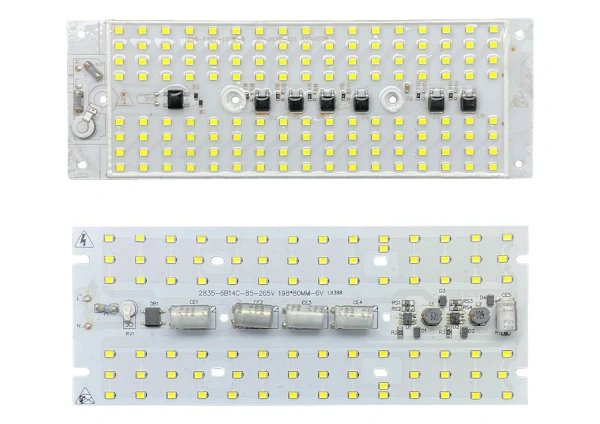

3. Alumina Substrates for LEDs

LEDs generate significant heat, so they need substrates that can keep them cool. Alumina ceramic substrates deliver high thermal dissipation and airtightness, which extend LED lifespan and brightness. Their airtightness also makes them weather-resistant, making them ideal for outdoor LEDs, automotive lighting, and industrial fixtures.

#image_title

4 Tips to Check a Ceramic Substrate’s Quality

Not all alumina ceramic substrates are created equal. Here’s how to spot a high-quality one:

1. Review the Material Specs

A top-notch substrate uses chemically stable materials (resistant to high temps, acids, and alkalis) with high thermal conductivity. Ask for product specs or manufacturing docs to verify these details—reputable suppliers will happily share them.

2. Inspect the Craftsmanship

Quality substrates have precise component spacing, tight bonding between layers, a flat surface, and smooth edges. Rough edges or uneven surfaces are red flags for poor machining.

3. Test Its Performance

Heat conduction is a key strength—test it by running the substrate for a while, then powering off and checking temperature and current flow. If it overheats quickly, its thermal conductivity is subpar.

4. Research the Manufacturer

Choose manufacturers with certifications, strict production processes, and positive reviews. A reputable brand with a track record of quality is more likely to deliver reliable substrates.

Ceramic Substrates in PCB Prototyping: Why GreatPCB Stands Out

Ceramic substrates are specialty materials, requiring advanced technology, precise machining, and careful handling. They’re also more expensive than regular PCBs, which is why many prototyping shops avoid small orders or struggle with complex builds.

But at GreatPCB, we specialize in ceramic substrate PCB prototyping. Our expertise lets us handle:

- Pure ceramic lamination (4–6 layers)

- Hybrid lamination (4–8 layers)

Whether you need substrates for high-power LEDs, industrial modules, or high-frequency circuits, we deliver precision, reliability, and quick turnaround—even for small-batch orders.

Alumina ceramic substrates are revolutionizing industries with their heat resistance, reliability, and versatility. When you need top-quality ceramic substrate PCBs, trust GreatPCB to bring your designs to life—with the expertise and precision your project deserves. Contact us today to get started!

Related Posts

PCBA Prototype

December 14, 2025

PCB Assembly

September 2, 2025