Common PCB Design DFM problems when you start the design

How can we design to maximize yield, reduce costs, and shorten delivery? DFM (Design for Manufacturability) pitfalls in PCB design are a major cause of yield decline, cost increases, and even project rework. Here are some of the most common DFM pitfalls engineers fall into and how to avoid them:

★ Hole design trap

❶ Plate thickness/hole diameter greater than 8

Risks: Increased difficulty in electroplating at the board factory, poor uniformity of copper plating on the hole wall, and a high risk of hole copper breakage

Solution: For thicker plates, the minimum hole diameter should be larger. For example, for a 2.4mm thick plate, the minimum hole should be larger than 0.3mm.

❷Via hole design is located on the SMD pad

Risk: The soldering area is reduced, the solder paste flows out of the hole, and the parts are prone to poor soldering due to insufficient solder.

Solution: Via holes are not designed on pads (including BGA), and wire connections are used to ensure the conduction relationship. If there is insufficient space, the PCB board is filled with resin plug holes and electroplating.

❸The distance from the via hole edge to the surrounding conductors is insufficient

Risk: Insufficient safety spacing can easily lead to CAF, which affects product durability and reduces production yield.

Solution: The margin of the via hole should be no less than 0.2mm from the surrounding conductor. If there is insufficient space, the via hole can be designed as a blind or buried hole.

★ Circuit designtrap

❶Insufficient spacing between conductors

Risks: Low production yield, easy to cause unclean film etching; if it is a high voltage position, arc discharge breakdown

Solution: Increase the distance between conductors as much as possible. If there is high voltage, set a safety distance according to IPC standards (for example, AC100V requires a distance of no less than 0.5mm).

❷BGA pitch is small but BGA diameter is designed to be large

Risk: BGAs cannot be separated by solder paste (i.e., solder mask cannot be printed), resulting in a short circuit between two BGA pads of different networks.

Solution: Match the pitch to the BGA ball size (for example, for a 0.4mm pitch BGA, the BGA ball size should be around 0.2mm and the solder mask ink color should be green/blue).

❸The pad is tangent to or extends beyond the outer shape

Risk: The cutting tool may be damaged during PCB manufacturing and copper may be exposed on the edge of the finished board.

Solution: Ensure a safe distance between the pad and the outer shape (CNC requires 0.25mm, V-cut requires about 0.4mm, depending on the thickness of the board and the residual thickness)

❹ Impedance lines are designed with unequal spacing or width

Risk: Signal distortion due to reflection

Solution: Keep the impedance line of equal width and distance, and do not make 90-degree turns

★ Solder mask design trap

❶ Directly pull the window between the pads

Risk: Tin short circuit

Solution: The spacing is sufficient, the solder mask ink is printed between the pads, and the solder mask window design is 0.05mm larger than the single side of the pad

❷Surface treatment: tin spraying, design BGA balls with diameter less than 0.4mm on large copper sheet

Risk: Tin cannot be sprayed, and the pad is oxidized, resulting in poor tin absorption

Solution: Change the large copper sheet to a spider foot design to provide a large enough space for the substrate to breathe; or change the surface treatment to gold/OSP, etc.

❸The color of solder mask ink is bright black

Risk: IC or pad spacing is less than 0.23mm and solder bridges (i.e., solder shields) cannot be made.

Solution: Change the color of solder mask ink, regular green spacing is 0.17mm (solder mask spacing is 0.075mm), other color inks are 0.2mm (solder mask spacing is 0.1mm)

❹Via hole window connected to the pad

Risk: Tin flow and tin on the via hole ring lead to insufficient tin on the solder pad and poor component placement

Solution: Via holes are not designed with solder mask openings on the pad surface or the Via is spaced sufficiently apart from the pad to create a solder mask bridge.

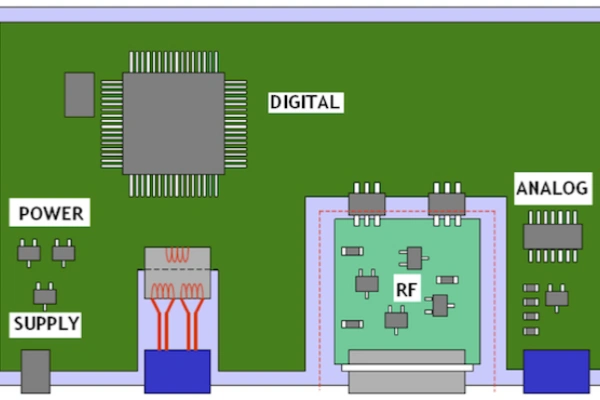

★ Stacking and layout design traps

❶Asymmetric stacking requirements

Risk: Severe board bending

Solution: The dielectric thickness/copper thickness is symmetrical, the copper area of the symmetrical layers is close, and the copper on the same layer is evenly distributed.

❷The connection position is designed to be close to the pad or trace

Risk: Stress from debonding the board causes pads/traces to peel, warp, or crack.

Solution: Avoid the connection position of the component, or ensure that there is at least 0.6mm distance from the pad or trace.

❸The shape of the mechanism is a special-shaped layout directly through the V-cut

Risk: Limited assembly or inability to fit into the mechanism

Solution: Add V-cut or hollow connection design between the boards

❹The spacing between boards during typesetting is less than 2mm

Risks: High production costs and low efficiency

Solution: The space between the plates should be no less than 2mm (including the width of the small pit inside the plate)

☆☆ Core principles for avoiding pitfalls:

- Advance communication: Obtain the board factory’s process capability documents (such as minimum line width/aperture, etc.) before designing

- Simulation verification: automatic checking of DFM rules

- Clear marking: Use layers to mark special requirements in the PCB file (such as impedance control value, resin plug hole, etc.)

- Archive the modification suggestions from the board factory into a checklist and continuously optimize

Manufacturability is not a post-fix, but a design consideration during the design process.

Read More: A Complete Guide through PCB Assembly Process Services

Related Posts

PCBA Prototype

March 25, 2025