A Complete Guide to LED PCB Manufacturing

With the rapid development of electronic technology, LED (Light Emitting Diode) has become an efficient, energy-saving light source that is widely used across various industries. As a key supporting component of LED technology, LED PCBs (Printed Circuit Boards) play a crucial role in optimizing LED performance. This article offers a thorough introduction to LED PCBs, covering their definition, base materials, design considerations, assembly process, industry applications, and advantages.

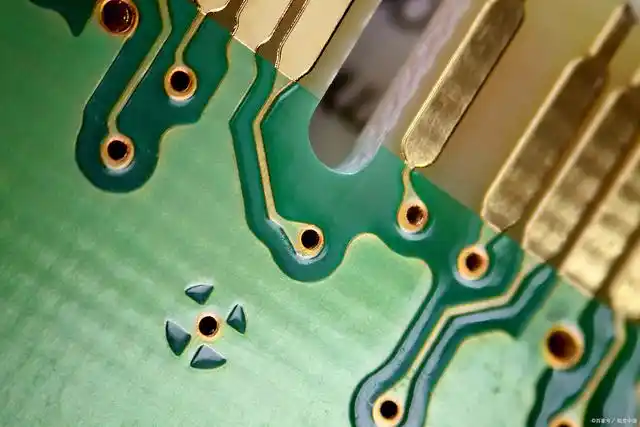

1. What Is an LED PCB?

An LED PCB is a specially designed printed circuit board for LED applications. It connects multiple LED components via printed circuitry, providing both electrical connections and mechanical support to ensure stable, efficient operation. Unlike conventional PCBs, LED PCBs must focus on managing the heat generated by the LEDs to ensure their longevity and performance.

2. Base Materials of LED PCBs and Their Differences

Aluminum-Based PCB

Aluminum PCBs are the most widely used base material for LED PCBs. They offer excellent heat dissipation due to aluminum’s superior thermal conductivity and the specialized thermal insulation layer in the PCB design. Aluminum-based PCBs are cost-effective, lightweight, and easy to manufacture, making them ideal for applications like indoor lighting, streetlights, and more. However, their electrical performance is less suitable for high-frequency, high-speed signal transmission.Ceramic-Based PCB

Ceramic PCBs offer excellent heat dissipation and electrical performance. Ceramic materials have high thermal conductivity and good insulation properties, making them suitable for high-power LEDs and applications requiring high electrical performance, such as automotive headlights and industrial lighting. However, ceramic PCBs are difficult to process and come at a higher cost, limiting their widespread use.Fiberglass-Based PCB

Fiberglass PCBs are made of glass fiber reinforced epoxy resin and are commonly used for traditional PCBs. They offer good mechanical and electrical insulating properties, with relatively low costs and easy manufacturing processes. However, their thermal performance is not as good as aluminum or ceramic-based PCBs, and they are typically used for low-power LEDs or applications with less stringent thermal requirements, such as indicator lights and small displays.Copper-Based PCB

Copper PCBs are made with copper as the base material, offering superior heat dissipation and conductivity compared to aluminum. They perform exceptionally well in LED light circuit board design that requires higher power and frequency. However, copper PCBs are more expensive and denser, and they require additional protective measures to prevent corrosion when exposed to acidic substances.

3. Design Considerations for LED PCBs

Heat Management

Heat dissipation is one of the most critical factors in LED PCB board design. Proper layout and thermal design, such as increasing copper foil area and incorporating heat sinks or vias, are essential for ensuring efficient heat transfer and preventing thermal degradation of the LED light circuit board.Electrical Design

To ensure reliable electrical connections, the resistance, capacitance, and inductance of the circuits must be precisely calculated. It’s essential to design power traces that can deliver stable voltage and current to the LED light PCB, while minimizing signal interference and transmission losses.Optical Design

Considerations like LED emission angle and light intensity distribution are essential for LED circuit board design. Proper packaging and lens selection can optimize the optical performance of the LED light PCB board, meeting the specific lighting needs of different applications.

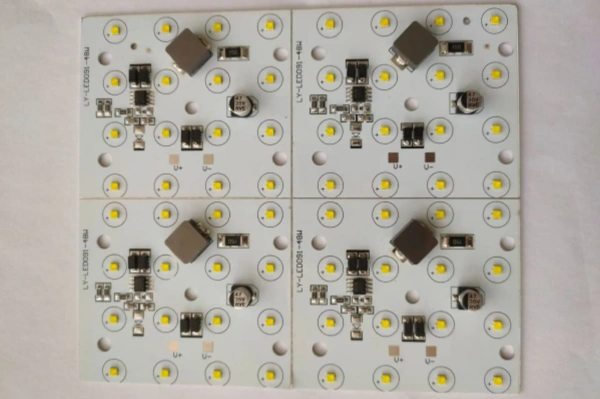

4. LED PCB Assembly Process

Stencil Printing of Solder Paste

Using a stencil to accurately print solder paste onto the PCB pads, ensuring uniform thickness and consistency for optimal soldering quality.Component Placement

High-precision pick-and-place machines are used to position LED components on the PCB, ensuring accuracy and improving production efficiency.Reflow Soldering

The PCB with mounted components is passed through a reflow oven, where the solder paste melts and secures the LED light PCB components. The process requires strict temperature control for optimal soldering.Inspection and Testing

After soldering, the LED circuit board undergoes thorough inspections, including visual checks and electrical performance tests, to ensure the quality and reliability of the assembled LED PCB.

5. Industry Applications

Lighting Industry

The most extensive application for LED PCBs, ranging from indoor lighting fixtures to streetlights and landscape lighting. With the energy efficiency and long lifespan of LEDs, coupled with the heat dissipation advantages of LED PCBs, lighting products have become more efficient and reliable.Automotive Industry

LED PCBs are used in automotive headlights, turn signals, and brake lights. Their excellent thermal performance and reliability meet the needs of automotive applications in complex environments, while the energy efficiency of LED light PCBs helps reduce overall energy consumption.Electronic Displays

For applications like LED displays and billboards, LED PCBs provide electrical connections and support for numerous LEDs, enabling bright and high-definition image displays.Medical Equipment

LED PCBs are essential in medical lighting, surgical lamps, and indicator lights in medical devices, ensuring stable performance and effective heat dissipation for continuous operation.Telecommunication Equipment

LED PCBs are used in indicators and displays in telecommunications equipment, helping to reduce failure rates caused by overheating and enhancing the functionality of the devices.

6. Advantages of LED Circuit Boards

Efficient Heat Dissipation

Effective heat management ensures the longevity of LED PCBs, preventing thermal degradation and ensuring stable operation.Energy Efficiency

LED light circuit boards optimize energy usage, further improving the energy efficiency of LEDs, aligning with the growing trend of energy conservation.Flexible Design

LED PCB design can be customized to meet the requirements of various shapes, sizes, and functionalities, fulfilling the diverse needs of different applications.High Reliability

Rigorous production and testing processes ensure the reliability of LED light PCB boards, minimizing product failures and ensuring long-lasting performance.Ease of Integration

LED PCBs can be easily integrated with other electronic components to form complete circuit systems, enhancing the overall performance and functionality of electronic devices.

With continuous advancements in technology, LED PCBs will continue to play a vital role in the development of the electronics industry, supporting innovation and providing reliable solutions for various sectors. As a leading choice for LED PCB design, they offer significant advantages in efficiency, performance, and environmental sustainability.

7. Why Choose GreatPCB for Your LED PCB Needs?

At GreatPCB, we’re a trusted leader in the LED PCB industry, known for our innovation, precision manufacturing, and customer-focused service.

- Innovation: Our R&D team constantly pushes the boundaries of LED PCB technology, ensuring our products meet the specific requirements of high-performance applications.

- Advanced Manufacturing: We invest in state-of-the-art equipment, ensuring high-quality production with precision and efficiency.

- Customer-Centric: We work closely with customers to provide custom solutions, offering real-time tracking, quality control, and after-sales support.

Whether you are working on a large-scale industrial design or a small consumer device, GreatPCB has the expertise and resources to meet your LED PCB needs.

Related Posts

PCBA Prototype

January 25, 2026

PCBA Prototype

December 8, 2025