Cost Control Strategies for Mass Producing PCBs

Reducing the cost of PCB boards directly translates to lowering the overall cost of electronic products. For the electronic manufacturing industry, PCBs are indispensable key components. Optimizing their costs not only helps companies gain an edge in fierce market competition but also enhances the cost-effectiveness of products. Therefore, how to reduce the cost of PCBs is a widely discussed topic in the industry.

1. Optimize Design to Improve Efficiency

The PCB design phase is a crucial factor affecting cost. During the design process, careful consideration should be given to the size, number of layers, and routing rationality of the circuit board. By reducing excessive layers and optimizing routing paths, material usage can be significantly decreased. Additionally, standardized designs help minimize special requirements during custom processing, thereby reducing production complexity.

2. Choose Appropriate Materials

The choice of materials directly impacts the cost of PCBs. It is advisable to select substrates that meet performance requirements while being reasonably priced. For instance, in high-frequency applications, appropriate high-frequency materials can replace expensive top-tier materials; in cases where heat resistance and mechanical strength are not critical, more cost-effective FR-4 materials can be chosen. Suitable materials not only meet product demands but also effectively reduce unnecessary costs.

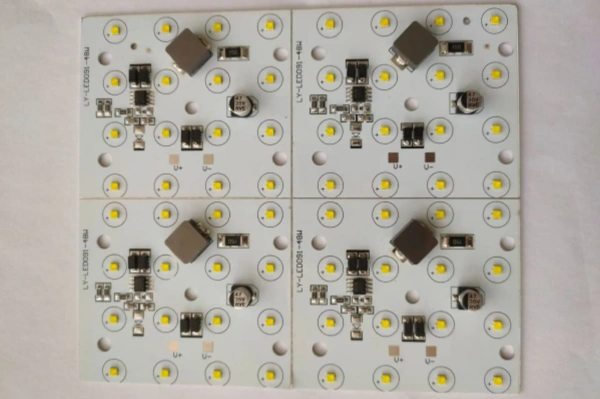

3. Mass Production to Lower Unit Prices

In PCB manufacturing, mass production is key to controlling costs. When order volumes are sufficiently large, suppliers can utilize more efficient production processes and equipment, thereby spreading out production costs. For small and medium enterprises, placing joint orders with other companies can create a bulk effect, allowing them to enjoy supply chain cost advantages.

4. Improve Production Yield to Reduce Rework Costs

The yield rate in PCB production directly affects final costs. A high yield rate means fewer reworks and defective products, which lowers labor and material losses during production. Therefore, choosing experienced and technically mature manufacturers, strengthening control over production processes, and regularly maintaining and calibrating production equipment can effectively enhance production stability and reduce rework costs.

5. Choose Suppliers Wisely

There are numerous PCB suppliers in the market, each with different pricing strategies and production capabilities. Companies should consider suppliers’ production capacity, delivery speed, quality assurance systems, and price levels comprehensively to select the most cost-effective supplier. Establishing a long-term stable partnership can also lead to more competitive pricing in future negotiations.

6. Pay Attention to New Technologies and Processes

With continuous technological advancements, many new manufacturing processes, such as flexible circuit board technology and 3D printing, are gradually being applied in PCB manufacturing. These new technologies can significantly reduce material waste, improve production efficiency, and, in some cases, further lower costs. Therefore, staying updated on industry trends and actively adopting advanced processes is a vital approach to cost reduction.

Reducing the cost of PCB boards is not only an important means to optimize product cost structures but also a key to enhancing market competitiveness. By optimizing design, material selection, production processes, and supply chain management, companies can effectively lower production costs while ensuring quality, thereby providing significant advantages for overall cost control in electronic products.

Related Posts

PCBA Prototype

January 25, 2026