How Do Rigid-Flex PCBs Redefine Prototype Circuit Assembly?

In this age of light-speed design for electronics, getting an idea on its way as a working prototype requires creativity, precision, and adaptability. The ancient printed circuit boards (PCBs), rigid or flexible, date back to the decades. Electronics no longer being big and performance-oriented, designers require more enlightened solutions.

That is where Rigid-Flex PCB steps in and revamps prototype circuit assembly fabrication, testing, and production.

Understanding Rigid-Flex Printed Circuit

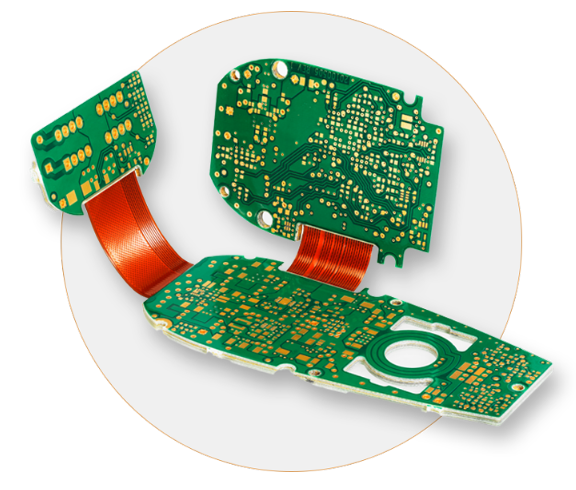

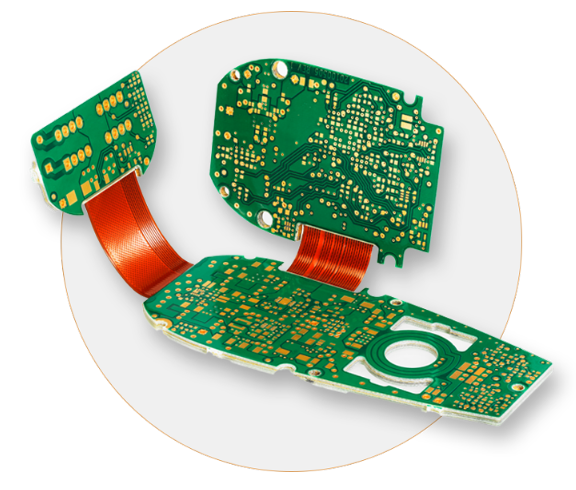

Rigid-Flex PCBs take the best from the classically used rigid boards and flexible circuits. In simple terms, the boards consist of multiple rigid and flexuous layers all in one single assembly. The rigid sections can offer mechanical support to the component parts, and the flexible sections can bend, fold, and nest in close quarters in constrained space.

Unlike the traditional hard PCBs with connectors or cables for the interconnections among the parts, Rigid-Flex configurations have fewer interconnections, achieving a more compact and more reliable assembly, a prototyping breakthrough.

#Rigid-Flex PCB

Increased Design Freedom and Miniaturization

Prototype circuit board assembly in today’s world, particularly those of consumer electronics, wearables, and medical devices, must be shrunk but without compromising performance. The purpose of shrinking the prototypes is achieved through Rigid-Flex PCBs’ use of stacked and bent circuits in three-dimensional shapes.

Whereas the board came with the restrictions inherent in a flat board, the engineers can now route traces outside the confines of folds and layers. Not only does it minimize the entire size of the device, but it also shows superior mechanical stability. Rigid-Flex PCBs are optimal in prototype applications where millimeter accuracy matters most.

Increased Reliability in Prototype Circuit Building

Every prototype will check the feasibility of a concept, and most important is reliability. Conventional assemblies tend to use connectors, wire, and solder points to bridge several stiff boards. All these are potential points of failure.

Rigid-Flex PCBs obviate the majority of such weak links with the aid of continuous electrical contact between rigid and flexible areas. It enhances signal integrity, reduces chances of short-circuiting or disconnection, and makes the board proof against vibration and mechanical stress.

With proof-of-concept prototypes where devices are tested repeatedly and toyed with, this reliability means that the devices perform consistently from one test to another, saving time and cost in the long run.

Simplified Assembly and Lightweight Construction

The second key advantage occurs at assembly. Prototype connector and wiring geometries are typically very challenging at assembly when several boards are interconnected together in tight spaces. Its inclusion of Rigid-Flex methods enables such types of connections to become a natural component of the layout of the circuits, making assembly easier and reducing labor costs.

In addition, since wires and fat connectors are eliminated with Rigid-Flex PCBs, weight savings are maximized, which is essential in aerospace, automotive, and handheld electronic applications. The lighter the prototype, the more it will approach the final product’s optimal design and performance.

Time and Cost Effectiveness in Prototyping

Even though Rigid-Flex PCBs appear more expensive to produce and design at first, they are cheaper from the prototype perspective. That’s the result of fewer part counts, less difficult assembly, and less rework.

Since the board’s interconnects are embedded in the board, no time is spent fixing connection problems or debating over wiring schemes. The simplified process allows prototype turnover rates to come down and the concept verification happens faster.

Where the time-to-market in mission-critical product design cycles becomes paramount, the competitive advantage for Rigid-Flex PCBs becomes obvious.

Backward Compatibility with Future-Generation Materials and Technologies

Rigid-Flex PCBs also accommodate future-generation copper-clad laminate and high-end substrates capable of withstanding severe environmental stresses. It enables the prototype of new material or high-end properties.

When used in high-rate communication, implantable medical applications, or rugged defense electronics, Rigid-Flex technology’s versatility ensures prototypes operate reliably across a broad spectrum of applications.

Inventing Electronics Today

Together with the evolving technology are the growing demands put on their base circuitry. Rigid-Flex PCBs’ smooth integration, low weight, and mechanical versatility compel engineers to innovate in design and potential.

By prototype circuit assembly reengineering and testing and design, the technology fills the gap from concept straight through production-grade design, moving new ideas from possibility into operational reality at rates faster than previously ever achieved.

Conclusion

Rigid-Flex PCBs are more than the sum of the words ‘rigid’ and ‘flex’ boards; they are the epitome of prototype assembly innovation in circuits. Due to their smaller size, high reliability, and ease of manufacturing, they are ideal for engineers to produce smart, rugged prototypes that capture innovation at its best today.

As business applications keep demanding smaller, faster, and more capable electronics, Rigid-Flex PCBs will play the leading role in prototyping, dictating the future of bringing ideas to life.

Related Posts

PCBA Prototype

December 30, 2025

PCBA Prototype

December 20, 2025