Overcoming Electrical Testing Challenges in PCBA Processing

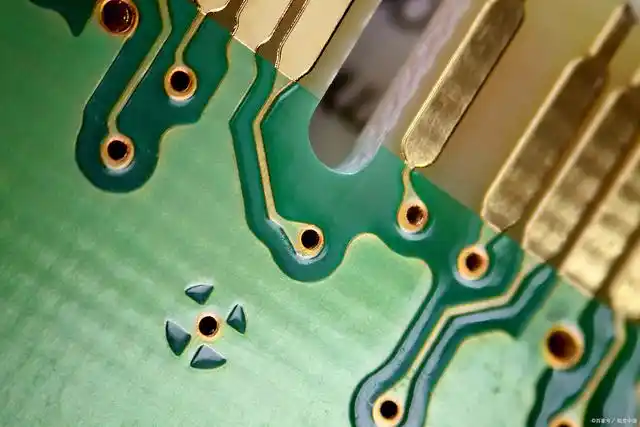

In modern electronics manufacturing, PCBA (Printed Circuit Board Assembly) processing is a key stage. Electrical testing is a crucial step in ensuring the quality and performance of PCBA products. However, this process faces numerous challenges. This article will explore the challenges of electrical testing in PCBA processing and propose corresponding solutions to help companies enhance product quality.

1. Challenges of Electrical Testing

1.1 Precision Issues

In PCBA processing, testing precision is vital. Given the multitude of components and complex layouts on the circuit board, testing equipment must accurately identify the function of each component. Insufficient precision in testing equipment can lead to inaccurate results, adversely affecting the final product quality.

1.2 Testing Difficulty of Complex Circuits

Modern electronic products have increasingly complex circuits, and the number of integrated circuit modules in PCBA is also on the rise. This complicates electrical testing, as complex circuits require more advanced testing technology and equipment to ensure that each module functions properly.

1.3 Testing Time and Cost

Electrical testing demands not only high precision but also timely completion. Extended testing times can increase production costs and impact production line efficiency. Thus, finding ways to shorten testing time while maintaining quality is a pressing issue.

2. Solutions

2.1 Investing in Advanced Testing Equipment

To enhance testing precision, companies should invest in advanced electrical testing equipment. Automated Testing Systems (ATS) and high-precision instruments can significantly improve testing accuracy. These devices leverage advanced algorithms and precise sensors to detect issues on the circuit board.

2.2 Implementing Intelligent Testing Technologies

With technological advancements, intelligent testing technologies are increasingly being applied in PCBA processing. Intelligent testing systems can monitor the testing process in real time, automatically adjust testing parameters, and improve flexibility and efficiency. The introduction of Artificial Intelligence (AI) can also help identify and predict potential electrical faults, further enhancing testing quality.

2.3 Optimizing Testing Processes

Companies can shorten testing time by optimizing their testing processes. For example, adopting parallel testing techniques allows multiple testing tasks to be conducted simultaneously, effectively reducing overall testing time. Continuous improvement and optimization of testing processes can also boost efficiency and lower production costs.

2.4 Enhancing Employee Training

Highly skilled operators are essential for ensuring testing accuracy. Companies should invest in training to enhance employees’ operational skills and troubleshooting abilities regarding electrical testing equipment. Systematic training can minimize human errors and improve testing quality.

2.5 Implementing Comprehensive Quality Management

A comprehensive quality management system is crucial for ensuring the reliability and effectiveness of electrical testing. Companies should establish stringent quality standards and conduct thorough quality control throughout the testing process. This includes regular maintenance and calibration of testing equipment, as well as detailed recording and analysis of testing results.

Conclusion

Electrical testing in PCBA processing is a key step in ensuring product quality but faces numerous challenges. By investing in advanced equipment, adopting intelligent technologies, optimizing processes, enhancing training, and implementing comprehensive quality management, companies can effectively tackle these challenges and improve the quality of electrical testing in PCBA processing. Only by continuously improving testing capabilities can companies thrive in a competitive market.

Related Posts

PCBA Prototype

April 6, 2025

PCBA Prototype

March 25, 2025