The Impact of RoHS Standards on SMT Processing: Challenges and Strategies

In today’s global manufacturing industry, the RoHS standard (Restriction of Hazardous Substances) has become an important factor that cannot be ignored.

As an SMT processing factory, we are keenly aware of the profound impact the RoHS standard has on SMT chip processing. This article will explore this topic from multiple dimensions, aiming to provide reference for peers and related industries.

Core Content of the RoHS Standard

The RoHS directive was approved by the European Union on January 27, 2003, with the aim of restricting the use of certain hazardous substances in electrical and electronic equipment, including lead (Pb), mercury (Hg), cadmium (Cd), hexavalent chromium (Cr^6+), polybrominated biphenyls (PBB), and polybrominated diphenyl ethers (PBDE). The use of these substances in electronic products is strictly limited, for example, the lead content in electronic products must not exceed 0.1% (1000 ppm), and cadmium content must not exceed 0.01% (100 ppm). These restrictions ensure the environmental friendliness of electronic products and reduce potential harm to the environment and human health.

Impact of RoHS Standards on SMT Chip Processing

Changes in Solder Properties

The RoHS standard requires the use of lead-free solder instead of traditional leaded solder. There are significant differences between lead-free and leaded solder in terms of flow and diffusion characteristics and melting point temperatures. Lead-free solder has poorer flow and diffusion properties, which requires SMT chip processing to make corresponding adjustments in printing accuracy, placement accuracy, and oven temperature settings to ensure soldering quality. For example, the oven temperature usually needs to be raised to above 235°C to meet the high-temperature requirements of lead-free solder.

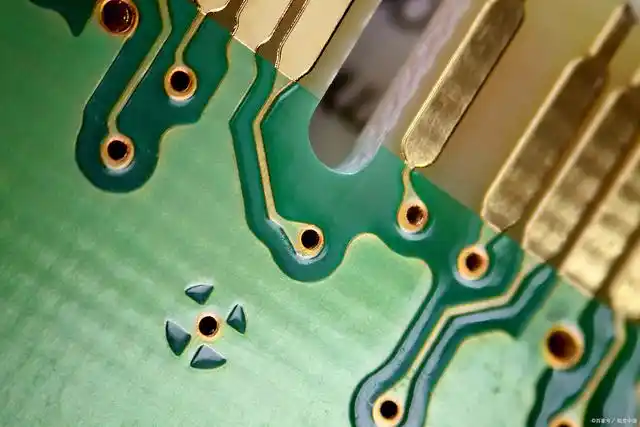

Selection of PCB Materials

The RoHS standard has also impacted the selection of PCB materials. Traditional FR4 materials may be damaged at high temperatures, so SMT processing factories need to assess and choose PCB materials that can withstand the thermal shock of lead-free soldering, such as Tg materials. This change not only increases material costs but also places higher demands on PCB design and manufacturing.

Process Flow Adjustments

The RoHS standard has prompted adjustments in the process flow of SMT chip processing. For example, during lead-free reflow soldering, it is necessary to optimize the temperature profile to ensure soldering quality. Additionally, due to the poorer flow and wetting properties of lead-free solder, issues such as solder dross and dull, rough solder joint appearances can easily arise, necessitating regular maintenance and cleaning of soldering equipment.

Increased Environmental Requirements

The RoHS standard not only focuses on the restriction of hazardous substances but also promotes environmental progress across the entire electronics manufacturing industry. SMT processing factories must strictly comply with relevant environmental regulations to ensure that waste and pollutants generated during production are effectively managed. Furthermore, RoHS certification requires manufacturers to provide detailed technical documentation and compliance declarations to demonstrate that their products meet environmental standards.

Strategies for Responding to RoHS Standards

In the face of challenges posed by the RoHS standard, SMT processing factories need to adopt a series of strategies to ensure smooth production and product quality. These include:

- Strengthening Technological Research and Development: Continuously improving lead-free soldering technology, optimizing process flows, and enhancing production efficiency and quality.

- Strict Supply Chain Management: Ensuring that all components and materials comply with RoHS standards, controlling the use of hazardous substances from the source.

- Enhancing Employee Training: Increasing employee awareness of RoHS standards and operational skills to ensure effective implementation of environmental requirements during production.

- Establishing a Quality Management System: Creating a comprehensive quality management system to monitor and test the production process, ensuring that product quality meets customer requirements and relevant standards.

The impact of the RoHS standard on SMT chip processing is multifaceted, bringing both challenges and opportunities. As an SMT processing factory, we actively respond to environmental requirements, continuously enhancing our technical and management levels to adapt to market changes and demands.

Related Posts

PCBA Prototype

April 6, 2025

PCBA Prototype

March 25, 2025