The Integration Design of Optical Sensors and PCBs

By PCBA PrototypePublished On: 2025-01-07Categories: Technical0 Comments on The Integration Design of Optical Sensors and PCBs

By PCBA PrototypePublished On: 2025-01-07Categories: Technical0 Comments on The Integration Design of Optical Sensors and PCBs

1. Introduction

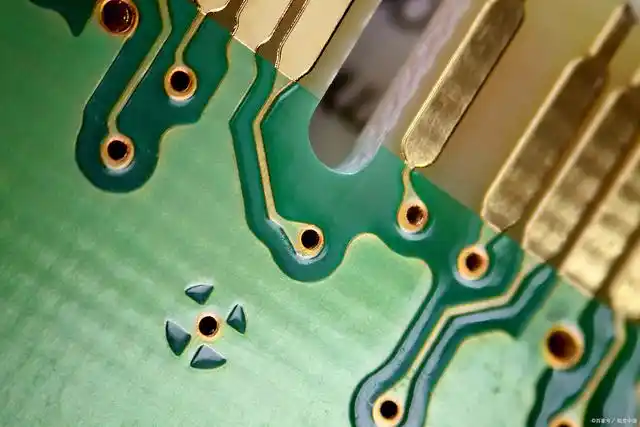

In the era of rapid technological advancement, the integration of optical sensors and printed circuit boards (PCBs) has become a crucial aspect in various electronic devices. This integration not only enables the miniaturization and high – performance of products but also expands their application scenarios, from consumer electronics like smartphones and cameras to industrial automation, medical devices, and aerospace.

2. Key Considerations in the Integration Design

2.1 Sensor Selection

The first step in the integration design is choosing the appropriate optical sensor. There are diverse types of optical sensors, such as photodiodes, phototransistors, charge – coupled devices (CCDs), and complementary metal – oxide – semiconductor (CMOS) image sensors. Each has its unique characteristics. For example, photodiodes are known for their high sensitivity and fast response time, suitable for applications requiring quick light detection, like optical communication receivers. CCDs offer excellent image quality with high – resolution imaging, while CMOS image sensors are more power – efficient and cost – effective, which are widely used in mobile devices.

When selecting an optical sensor, factors like the required sensitivity, spectral response range, resolution (for imaging sensors), and response time must be carefully considered according to the specific application requirements.

2.2 PCB Design for Compatibility

2.2.1 Material Selection

The choice of PCB material is fundamental. High – frequency and high – performance applications often require materials with low dielectric loss, such as Rogers materials. These materials can effectively reduce signal attenuation, especially when dealing with high – speed data transmission from optical sensors. For applications where cost is a major concern, traditional FR – 4 materials can still be a viable option, but proper design techniques need to be employed to mitigate the impact of higher dielectric loss.

2.2.2 Layer Stacking

The number of layers in a PCB affects the overall performance and complexity of the integration. For simple optical sensor applications with relatively few components, a two – layer or four – layer PCB might be sufficient. However, in more complex systems, such as high – end cameras with multiple sensors and high – speed data processing chips, a multi – layer PCB (e.g., 8 – layer or 16 – layer) is often necessary. The layer stacking should be designed to separate power planes, ground planes, and signal layers properly to minimize electromagnetic interference (EMI).

2.2.3 Layout and Routing

The layout of the optical sensor on the PCB is critical. The sensor should be placed in an area that is free from mechanical stress and has easy access to light sources (if applicable). Signal traces from the sensor to other components should be as short as possible to reduce signal attenuation and interference. When routing power and signal lines, techniques such as differential signaling should be used for high – speed signals. Power lines need to be wide enough to handle the current requirements of the sensor without significant voltage drops.

3. Challenges and Solutions in the Integration

3.1 Thermal Management

Optical sensors can generate heat during operation, especially in high – performance applications. Excessive heat can affect the accuracy and reliability of the sensor. To address this issue, thermal vias can be added in the PCB design to transfer heat from the sensor to the outer layers of the PCB, where it can be dissipated more effectively. Additionally, heat sinks can be attached to the PCB in close proximity to the sensor. The use of thermal interface materials between the sensor, heat sink, and PCB helps to improve heat transfer efficiency.

3.2 EMI Protection

EMI can interfere with the signals from optical sensors, leading to inaccurate readings or malfunctions. To prevent EMI, the PCB should be designed with proper shielding. This can be achieved by using a metal enclosure around the sensor area or by creating a ground plane that surrounds the sensor and its associated circuitry. Ferrite beads can be added to power lines to filter out high – frequency noise. Signal traces should be routed away from sources of interference, such as high – power digital circuits.

4. Conclusion

The integration of optical sensors and PCBs is a complex yet rewarding process. By carefully considering sensor selection, PCB design for compatibility, and addressing challenges such as thermal management and EMI protection, manufacturers can create high – performance electronic devices that meet the demands of modern applications. As technology continues to evolve, further innovation in the integration design of optical sensors and PCBs will open up new possibilities for a wide range of industries.

Related Posts

PCBA Prototype

April 6, 2025

PCBA Prototype

March 25, 2025