An overview of Printed Circuit Boards (PCBs): The Pillars of Electronic Industry

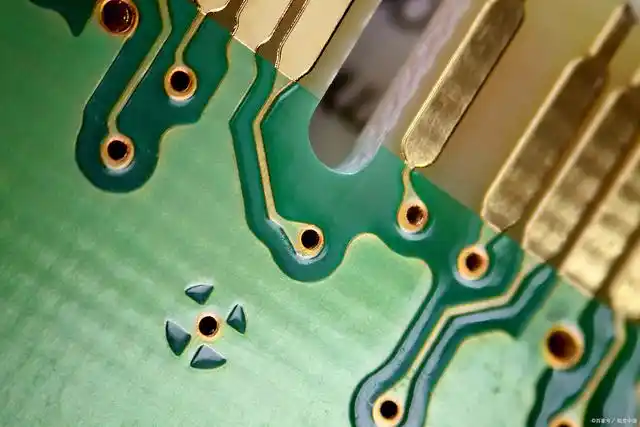

A Printed Circuit Board (PCB) is a flat board with conductive trails engraved on its surface. The material used for PCB is generally non-conductive such as fiberglass or composite epoxy. The conductive trails acts as medium for signals to travel between the components soldered on the PCB. The components such as resistors, capacitors, microchips are soldered on the board in such a way that they form a working electronic circuit.

These PCBs have fast become the backbone of the electronic industry. These PCBs are used in almost all the electronic appliances from smart phones to other devices used in different fields such as medical and mechanical. This blog will discuss the role of PCBs in different fields along with their types focusing on Flex Rigid PCB, PCB Assembly and PCB Assembly Factory.

Flex Rigid PCB

Flex Rigid PCB is hybrid combination of both flexible and rigid PCB technologies. This type of PCB processes the qualities of both rigid as well as flexible PCB. Flex Rigid PCBs can be bent and twisted according to the need while having the strength and longevity of a rigid PCB.

Flex Rigid PCBs are tailor made for the application in congested and tight spaces with complex and uneven shapes. These are often used in medical devices, electronic watches and smart phones. Flex Rigid PCBs posses following advantages:

- Less Space Requirements: The combination of flexible and rigid components cuts down the space required to mount multiple components in small devices.

- Enhanced Durability: The combined properties of rigid and flexible PCBs increase the toughness of the product to withstand high-stress while being flexible enough to allow movement without any damage.

- More Design Flexibility: Flex Rigid PCBs allow manufacturers to produce more complex, 3-D designs allowing more efficient layouts.

The PCB Assembly Process

The process of PCB Assembly is the process in which different electronic components are mounted on the PCB. This process can be done in different ways.

- Surface Mount Technology (SMT): SMT is used for small components like resistors, capacitors, and integrated circuits. In this method components are directly placed on PCB surface.

- Through-Hole Technology: This technique is used for used for larger components or those that need stronger mechanical connections. In this, components are drilled into PCB and then soldered with secure connection.

- Mixed Technology: This technique is used for PCBs which require both SMT and Through Hole Technique. This technique is used for PCBs for unique project needs. This is commonly used in high speed communication devices.

PCB Assembly Factory

PCB Assembly Factory is the hub of production of PCBs. PCB Assembly Factory is place with state-of –the art machinery and equally able and skilled personnel responsible for producing impeccable PCB pieces which meet the requirements.

There are different processes in a PCB Assembly Factory which are as follows:

- Design Verification:. The first step in production of PCB is its design. Before assemble commence, it is made sure that layout and components are perfect match.

- Solder Paste Application:. Before placing the components, PCB Assembly Factory applies solder paste to the board for placing the components.

- Component Placement: For placing the different components on the board, automated machines are used to ensure perfection.

- Soldering: In this process, solder paste is melted so that components are attached securely. This process is called reflow soldering.

- Inspection and Testing: Upon completion of above processes, finally the PCBs are properly inspected and tested. Different tests such as automated optical inspection and electrical testing is done to ensure no defects.

PCBs: The product for future.

With the increase in demand for more small and compact yet high-performance devices, PCBs are here to stay. More and more innovations are taking place in this field to meet the needs of ever growing industry.

Flex Rigid PCBs are becoming more and more popular as demand for more smaller, sophisticated and compact devices is increasing day by day.

Conclusion

Printed Circuit Boards PCBs have made it possible for modern electronic gadgets to be more compact and sophisticated with high performance. The demand for Flex Rigid PCBs in future will grow and PCBs will play an important role in technological advances of the future.

Related Posts

PCBA Prototype

January 25, 2026

PCBA Prototype

December 8, 2025