Importance of the PCB ink plug hole proces

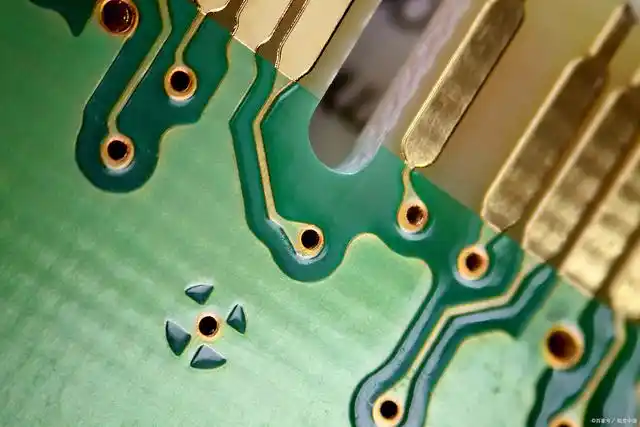

In the electronics manufacturing industry, the stability and reliability of PCB is crucial.The construction of the PCB ink plug hole process is one of the key steps to ensure the performance of the circuit board, which involves the use of special ink to fill the conductive hole to prevent short circuits between different layers.As a PCB&PCBA manufacturer, our design team has deepened the PCB ink plug hole process and can produce high quality products.

1. The importance of PCB ink plug holes

Prevent the short circuit: through the plug hole can effectively isolate the different conductive layers, to avoid the short circuit caused by current leakage.

Ensure signal integrity: a good plug hole process can reduce interference during signal transmission and maintain signal clarity and stability.

Improve the mechanical strength: the circuit board after the plug hole can better withstand the physical stress and improve the overall mechanical stability.

2.Key measures to ensure stability and reliability

Choose the right ink: according to the application requirements of the circuit board, choose the inks with good electrical insulation, high adhesion and good chemical resistance.

Precise control of the stopper process: strictly control the temperature, pressure and time during the stopper process to ensure that the ink is fully filled and cured.

Use high quality equipment: use high precision plug hole equipment to improve the quality and efficiency of the plug hole.

Implement strict quality inspection: through automatic optical inspection (AOI) and X-ray detection methods, the plug hole effect is fully tested.

3.Strategy for optimizing the plug hole process

Optimize the design circuit board layout: consider the demand of the plug hole in the design stage, avoid too dense hole layout, and ensure that the ink can be fully filled.

Material compatibility testing: conduct compatibility tests of inks and plates before production to ensure that their interactions comply.

Periodic maintenance of equipment: regularly maintain and calibration of the stopper equipment to maintain its best performance.

Continuous process improvement: Based on production feedback and reliability test results, continuously optimize the stopper process to improve the quality of PCB board.

summary

The PCB ink plug hole process is the key link to ensure the stability and reliability of the printed circuit board. custom printed circuit board manufacturers can select the right ink, accurately control the plug hole process, use high-quality equipment, and perform strict quality testing. At the same time, the optimization of the design layout, material compatibility testing, regular maintenance of equipment, and continuous improvement of the process, will further ensure the long-term stability and reliability of the circuit board. With the continuous progress of electronic technology, the requirements for PCB making are becoming higher and higher, which requires PCB manufacturers to continuously innovate and improve the plug hole technology to meet the challenges of the future electronics industry.

Related Posts

PCBA Prototype

April 6, 2025

PCBA Prototype

March 25, 2025