SMT PCB: The Core Technology of Electronics Manufacturing

In today’s fast-paced technological world, electronic devices are everywhere, from smartphones and computers we use daily to cars, medical devices, and industrial control systems. Behind these electronic products, Printed Circuit Boards (PCBs) and Surface Mount Technology (SMT) play key roles. SMT has revolutionized the electronics manufacturing landscape, making electronic products smaller, higher performing, and more reliable. In this article, we’ll dive deep into various aspects of SMT in PCB manufacturing, from the basic concepts and process flows to the challenges and future development trends.

1. Introduction to PCBs and SMT

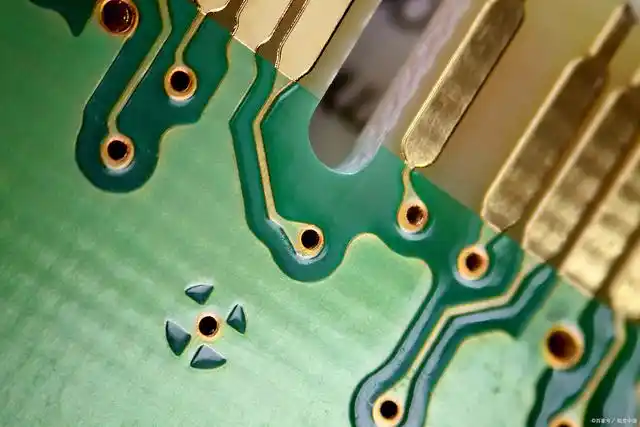

(a) PCB (Printed Circuit Board)

A PCB is a crucial part of any electronic product. It provides electrical connections and physical support for the electronic components. By etching conductive tracks onto an insulated substrate, PCBs enable signal transmission and power supply between components. With technological advancements, PCB designs have become increasingly complex, evolving from single-layer to multi-layer boards, and even to High-Density Interconnect (HDI) boards to meet the growing demands of electronic devices.

(b) SMT (Surface Mount Technology)

SMT is a technology for mounting surface-mounted devices (SMDs) directly onto the surface of a PCB. Unlike traditional through-hole mounting, which requires drilling holes in the PCB, SMT uses solder paste to adhere the components to the PCB pads, which are then soldered using processes like reflow soldering to create a strong electrical connection. SMT greatly enhances production efficiency and density, propelling the miniaturization, lightweighting, and high-performance nature of electronic products.

(c) Importance of SMT in Modern Electronics Manufacturing

In modern electronics manufacturing, SMT has become the mainstream technology, widely applied across various sectors. It boosts production efficiency, reduces costs, and improves product performance and reliability. As the demand for smaller, higher-performance products in the consumer electronics market continues to rise, SMT’s importance is more pronounced. Whether it’s mass-produced consumer electronics or high-reliability automotive electronics and medical devices, SMT plays an indispensable role.

(d) Benefits of Using SMT in PCB Assembly

- Miniaturization: SMT allows for smaller, more compact designs, significantly reducing the size and weight of electronic products. For instance, the mainboard in smartphones can integrate more functionality in limited space using SMT.

- Increased Reliability: SMT components form more solid mechanical connections with PCBs, reducing issues like solder joint loosening or poor contact due to vibration or shock, improving the reliability and stability of products.

- Cost Efficiency: SMT reduces production time and costs, such as eliminating the need for PCB hole drilling and other labor-intensive processes. With higher soldering reliability, repair costs are also minimized.

- Automation: SMT processes are ideal for high-speed, large-scale production. Automated equipment like pick-and-place machines and reflow ovens allow for efficient, precise production, improving production speed and product consistency.

- Performance Boost: SMT reduces component lead lengths and parasitic parameters, improving electrical performance, reducing signal delays, and minimizing electromagnetic interference, making electronic products better at handling high-frequency signals and complex circuit functions.

2. what is sMT

(a) SMT Definition and Core Principles

SMT is an electronic assembly technology that directly mounts surface-mounted devices (SMDs) on the PCB’s surface. The core principle involves precise mechanical placement and soldering processes, ensuring strong electrical connections and mechanical fixation between SMDs and PCBs. The key to SMT is using solder paste as the medium to attach SMDs onto PCB pads, then heating to melt the paste and form solid solder joints.

(b) Key Components Involved in SMT (SMD – Surface Mount Devices)

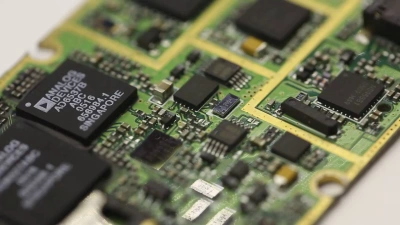

- Passive Components (Resistors, Capacitors, Inductors): These are fundamental electronic parts. SMT versions of passive components are small and lightweight, fulfilling the demands of high-density assembly. For instance, surface-mount resistors and capacitors come in small sizes, such as 0402 and 0201 packages, saving PCB space.

- Integrated Circuits (ICs): ICs are core components of electronics. SMT technology enables complex ICs to be integrated into the PCB in smaller packages. For example, Ball Grid Array (BGA) ICs use solder balls on the bottom to connect to the PCB, achieving higher pin density and better electrical performance.

- Other Specialized Components: Components like oscillators, switches, and connectors also have corresponding SMT packages to meet diverse circuit design needs.

(c) SMT vs. Traditional Through-Hole Technology

- Component Installation Method: Traditional through-hole technology requires inserting component leads into holes in the PCB and soldering them on the other side, while SMT directly attaches components to the PCB’s surface without the need for drilling holes.

- Assembly Density: SMT offers much higher assembly density than through-hole technology, enabling more components to be installed on the same PCB area due to the smaller size of SMT components and the absence of space needed for pin holes.

- Production Efficiency: SMT suits automated production lines with faster production speeds and higher efficiency. In contrast, traditional through-hole mounting is more labor-intensive and slower, with higher labor costs.

- Electrical Performance: SMT reduces component lead lengths, minimizing parasitic inductance and capacitance, offering better electrical performance, especially in high-frequency circuits. Traditional through-hole technology has longer leads, making it more prone to signal interference and delays.

(d) Key Advantages of SMT in PCB Manufacturing

- Miniaturization: SMT makes it possible to design more compact and lightweight products, meeting consumer demand for portable devices. For example, tablets and wearable devices benefit from SMT’s miniaturization capabilities.

- Improved Reliability: The stronger solder joints in SMT reduce failures caused by mechanical vibrations and temperature changes, crucial for applications in harsh environments like automotive electronics.

- Cost Efficiency: SMT reduces PCB manufacturing costs by cutting down material and labor costs. Additionally, with improved production efficiency, total costs in mass production are significantly lower.

- Automation: SMT is highly automated, reducing human error and improving product consistency. Automated equipment like pick-and-place machines and reflow ovens ensure high-speed, precise component placement and soldering, enhancing production efficiency.

- Performance Improvement: SMT improves electrical performance by reducing signal transmission delays and electromagnetic interference, making it ideal for high-performance products like 5G communication devices and high-speed computers.

3. SMT Process in PCB Manufacturing

(a) Step 1: Solder Paste Application

Solder paste plays a key role in SMT by connecting SMDs to PCB pads. It is made from metal powders (such as tin-lead, tin-silver-copper) and flux. During component mounting, solder paste not only attaches SMDs to the PCB but also removes oxidation from metal surfaces, ensuring smooth soldering.

(b) Step 2: Component Placement

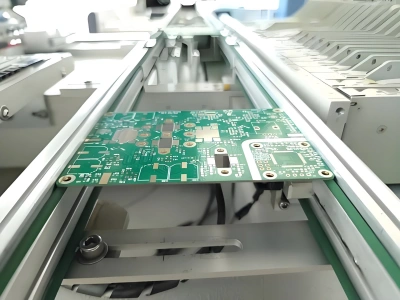

The pick-and-place machine is the core equipment in an SMT production line, accurately placing SMDs onto the PCB. It uses a vision system to identify and position the components, ensuring proper alignment and placement on the PCB.

(c) Step 3: Reflow Soldering

Reflow soldering melts the solder paste and forms strong electrical and mechanical connections between the SMDs and the PCB. The process involves heating the PCB through stages like preheat, ramp-up, reflow, and cooling.

(d) Step 4: Inspection and Testing

Automatic Optical Inspection (AOI) ensures that SMDs are correctly placed and soldered, detecting issues like misalignment or poor solder joints. Functional testing follows to check the electrical performance and functionality of the PCB to ensure it meets design specifications.

4. Challenges in SMT PCB Assembly

(a) Component Misalignment

Misalignment of components during SMT assembly can lead to poor electrical connections or product failure. This can be addressed by optimizing machine settings, regular calibration, and using advanced vision systems.

(b) Soldering Issues

Common soldering problems include tombstoning, bridging, and insufficient solder. These can be solved by adjusting solder paste application, optimizing reflow profiles, and ensuring proper pre-treatment of components.

(c) Thermal Management

As electronic devices become smaller and more powerful, managing heat within SMT assemblies is critical. Solutions like heat sinks, thermal gels, and optimized PCB layouts are essential to improving heat dissipation.

5. Future of SMT in PCB Manufacturing

SMT technology is evolving with advancements in AI, machine learning, and the Internet of Things (IoT), improving automation and production optimization. As components shrink and performance increases, SMT will continue to push the boundaries of miniaturization and efficiency, driving innovation in the electronics manufacturing industry.

Related Posts

PCBA Prototype

April 6, 2025

PCBA Prototype

March 25, 2025