What is Flex PCB Coverlay?

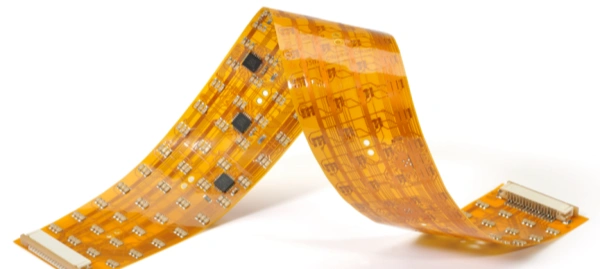

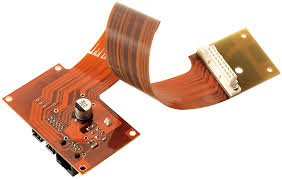

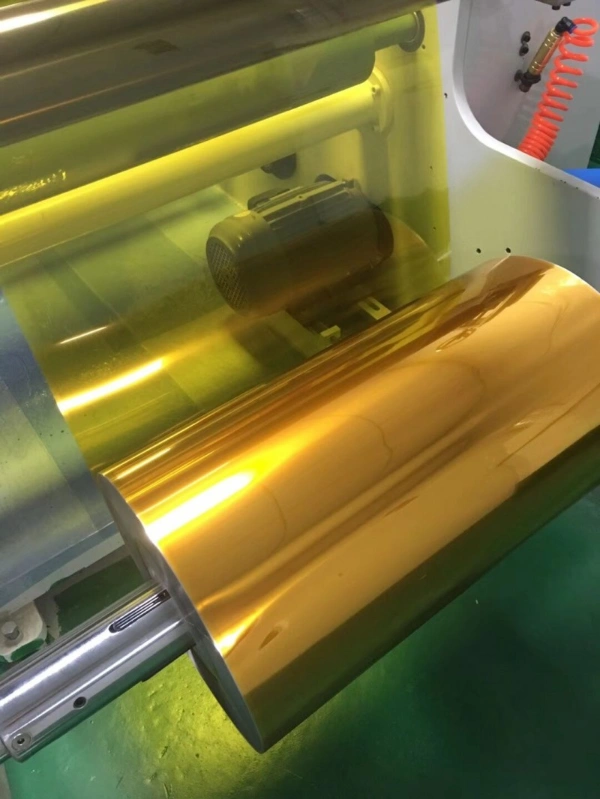

In the PCB making of flexible printed circuit boards, a material called a “coverlay” is involved in packaging and protecting the external circuit of the flexible circuit board. The coverlay consists of a solid polyimide and a flexible adhesive, followed by pressing and pressurizing under the heating conditions to the flexible printed circuit surface. Thus covering the flexible PCB surface to protect and isolate the circuit.

How to choose the appropriate flexible PCB coverlay?

The coverlay in the flexible PCB has various combinations of adhesives and film thickness. The common coverlay thickness is 0.001 “polyimide and 0.001” adhesive. Combination of 1:1 (1 mil film and 1 mil binder) ratio. The specific combination of the film and the adhesive is affected by the following factors:

- Minimum bending radius requirements: A thinner coverage may be required to meet the stringent bending requirements.

- Outer finished copper thickness: at least 1 mil (25μm) adhesive per ounce (35μm) of finished copper to ensure complete packaging. For example, an ounce of finished copper requires at least 1 mil adhesive.

- Dielectric pressure resistance.

What is the difference between the coverlay and the weld resistance layer of the flexible PCB?

- Design differences

Coverlay more giant nets are needed to improve the firmness of the FPC. A large lot of adhesive needs to be used to ensure correct lamination. SMT forms the electroplating through-hole opening by laser cutting, mold, etc. For the square openings, the minimum size of the overlay is approximately 0.6 mm. The weld resistance layer is used for rigid and flexible design. Unlike the overlay, it does not require multiple openings to design fine-spaced PCB elements.

- Highly flexible

Coverlay provides excellent flexibility and robustness in the curved area of the flexible circuit. The weld resistance layer cannot be compared to the excellent bendability of the cover PCB.

- Color

The eld resistance layer is available in PCB manufacturing and is dark green, white, and black. However, light brown is the most common color of the overburdened PCB.

- Material

The PCB covering material is an adhesive and polyimide with good electronic properties, and the flexible PCB resistance welding material is enhanced by epoxy resin.

The overlay mainly has the following functions

Circuit element protection: The cover layer serves as an outer layer to protect the circuit element on the flexible PCB from mechanical damage, dust, or chemical impurities.

Insulation: The overlay has insulation properties to prevent current flow between the circuit board surfaces. This is for ensuring the circuit is properly.

Maintain flexibility: Because the cover layer itself is flexible, it helps to maintain the flexibility and bending properties of the entire flexible PCB.

We’re a company specializing in the production of PCB&PCB Assembly services. If you want to know more details, please don’t hesitate to contact us. Our PCB engineers will answer it for you.